Regarding the pyrolysis products of waste tyres, the collection and processing technologies for pyrolysis gas and pyrolysis oil are relatively mature. However, carbon black from tyre pyrolysis is increasingly favored by researchers due to its complex composition and diverse applications.

The global pyrolytic carbon black market is experiencing a period of rapid growth. According to several industry research reports, its market size is projected to maintain a compound annual growth rate of over 10% until 2030.

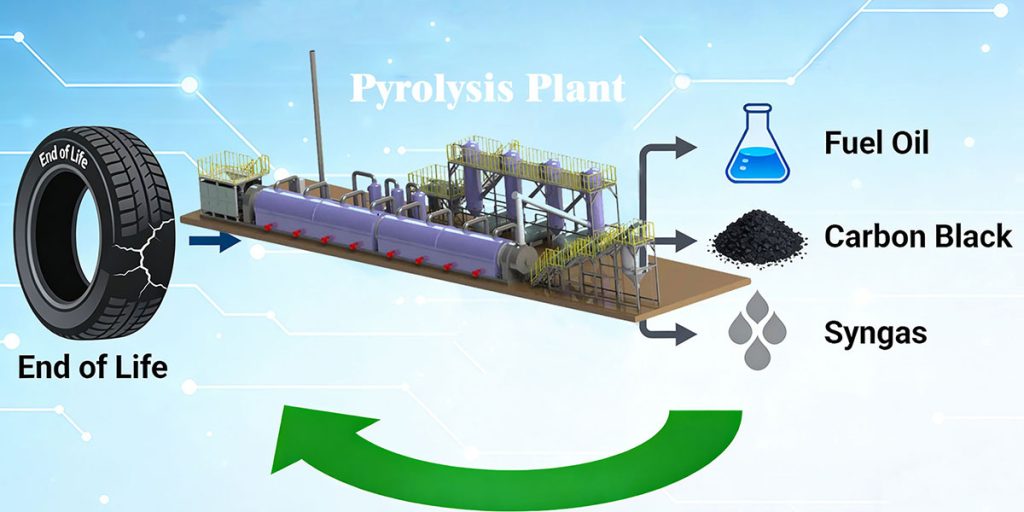

The tyre pyrolysis plant can convert waste tires into pyrolysis oil, carbon black, syngas and steel wire. The proportion of pyrolysis carbon black is 30%-35%. The production process is a complex and sophisticated process requiring the coordinated efforts of multiple steps.

For continuous pyrolysis equipment, the large volume of intact waste tires can affect pyrolysis efficiency. Waste tires require pre-treatment involving crushing and steel wire separation. The tires are processed into a size suitable for the continuous pyrolysis reactor. This improves thermal efficiency and reaction uniformity, and effectively prevents incomplete pyrolysis or hot spot problems.

Waste tires enter the reactor through the feed port, and the burner begins to heat the reactor. The pyrolysis reactor rotates to ensure uniform heating of the waste tires. The polymer compounds (such as rubber) in the tire particles undergo thermal decomposition reactions, breaking down into smaller molecular chains. The final products include fuel oil, carbon black, and combustible gas.

Carbon black is the main solid product of pyrolysis, with a content of approximately 30-40%. Fuel oil is one of the core high-value-added products of waste tire pyrolysis, usually with a yield of 35-50%.

The oil and gas generated from tire pyrolysis are transported through a gas channel to a condensation system to improve the recovery rate of fuel oil. Non-condensable gases are collected by a gas recovery device and can be used as fuel for the burners in the heating system. The flue gas generated by the burners in the heating system is purified through a desulfurization and denitrification device to meet environmental emission requirements.

To increase the added value of carbon black and meet the needs of high-end industries, further processing of the pyrolysis carbon black is required. Through processes such as grinding, granulation, and impurity removal, two types of tyre pyrolysis carbon black with different uses can be obtained: coarse carbon black and fine carbon black.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..