Technical Specifications

| Item | Content | ||

| Model | No. | Capacity | Operation |

| MJT-100 | 100KG/H | Fully continuous | |

| MJT-500 | 500KG/H | Fully continuous | |

| MJT-1000 | 1000KG/H | Fully continuous | |

| MJT-2000 | 2000KG/H | Fully continuous | |

| MJT-3000 | 3000KG/H | Fully continuous | |

| MJT-5000 | 5000KG/H | Fully continuous | |

| Accepted materials | Rice husk, saw dust, wood waste, straw, palm shell, coconut shell, | ||

| End products | Biochar/Charcoal, Syngas, Tar& Wood vinegar(optional) | ||

| Applicable fuel | Coal/natural gas/LPG/ Diesel/wood/pyrolysis oil | ||

| Material of reactor | 304 stainless steel | ||

| Reactor structure | Double cylinders | ||

| Cooling | Water Cooling | ||

| Land Required | 300-400m2 | ||

Raw Materials

Rice husk

Woody waste

Straw

Coconut shell

Jute rod

Sludge

Advantages of the System

Reactor structure takes dual cylinder type, which has long stroke and can ensure the biomass carbonized completely

Complete Reactor made of 304 stainless steel, which can resist high temperature and give the machine service life much longer

Fully Continuous operation, non-stop running, keep feeding and carbon discharging 24 hours per day, high automation,

The complete line takes modular design, which is easy for transportation and installation, save a lot of installation cost

The machine use it own produced syngas as main fuel during the carbonization, save a lot of energy cost

PLC control system, the process is fully automatic

Final Products

|

Name |

Picture |

Application |

|

Biochar/ charcoal |

|

Used as soil conditioner, carbon sequestration, improve the quality of soil Used as fuel for industry heating and cooling or BBQ Can be reprocessed into activated carbon, widely used in the smelting, chemical fields. |

|

Tar & Wood vinegar |

|

Widely used as a crop insecticide, make leaf surface fertilizer |

|

Syngas |

|

Can be recycled to heat the carbonization host. By this way, you can reduce a lot of fuel costs. |

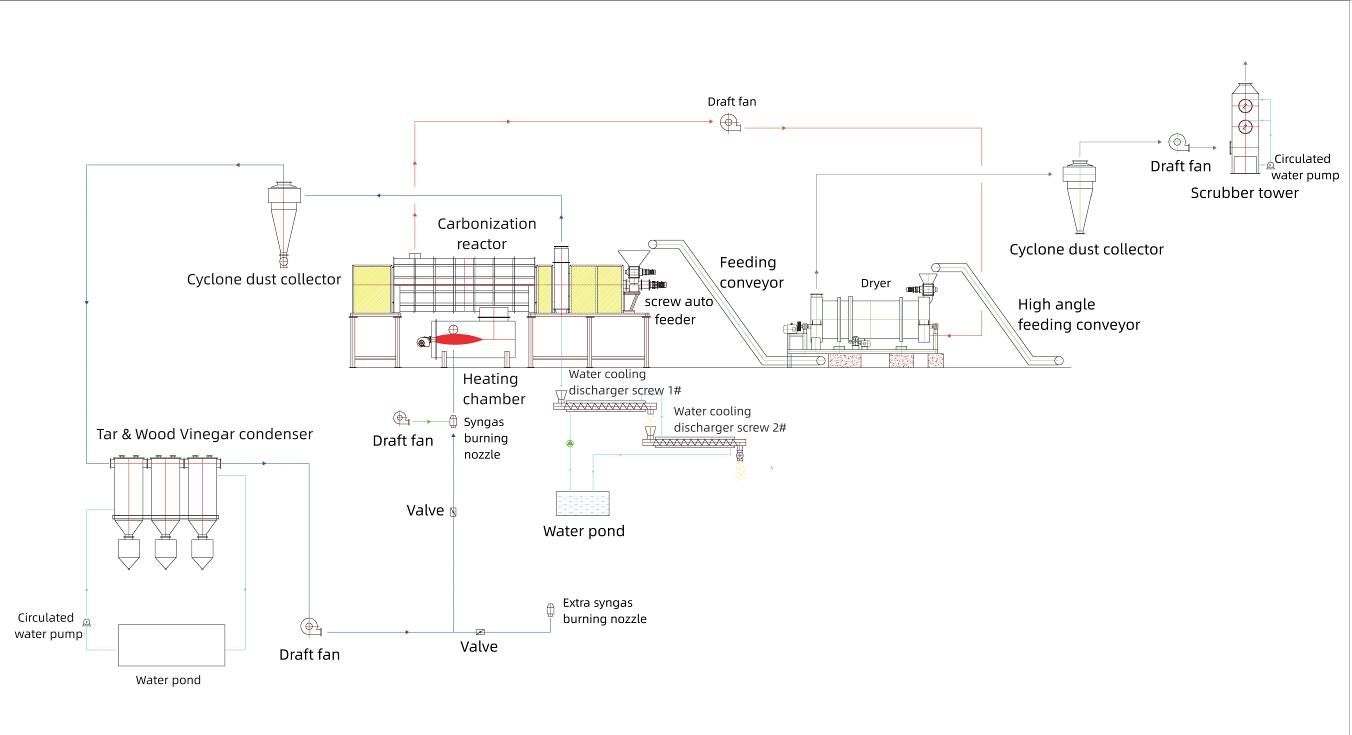

Flowing Diagram