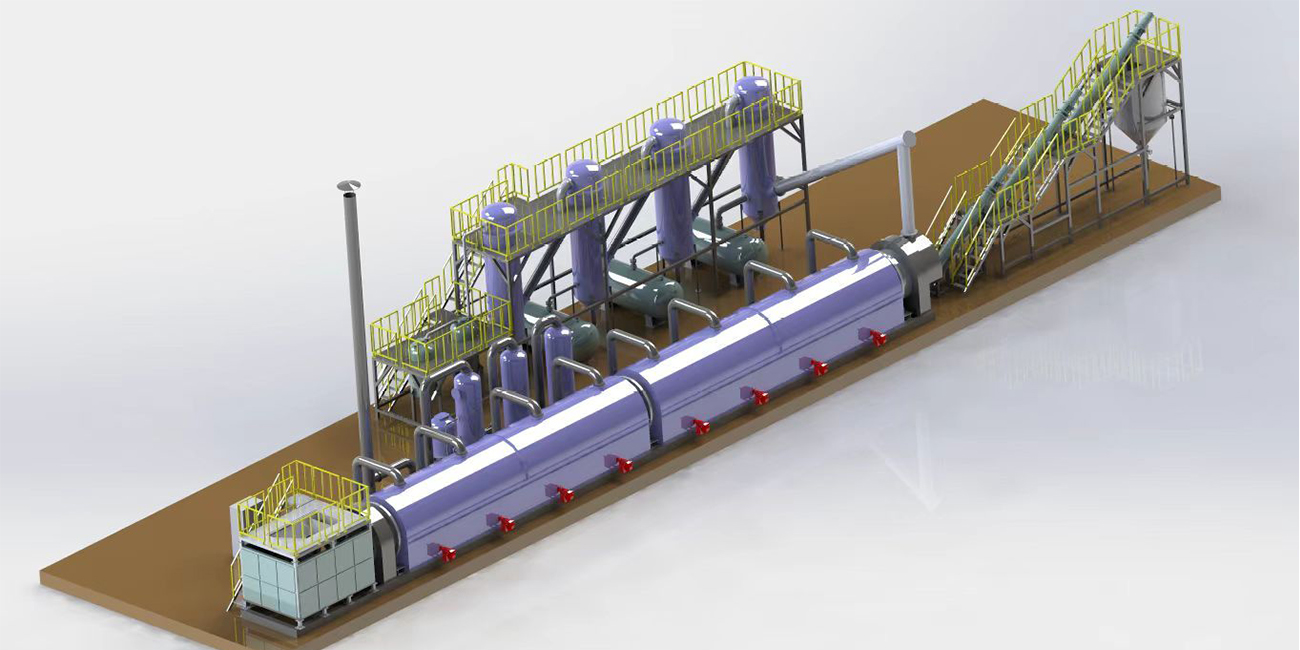

Technical Specifications

|

Item |

Content |

|||

|

Model |

No. |

Capacity |

Reactor Size |

Operation |

|

MJ-2 |

1-2T per batch |

1400*4000mm |

Batch |

|

|

MJ-6 |

6T/D |

2200*6000mm |

Batch |

|

|

MJ-10 |

8-10T/D |

2600*6600mm |

Batch |

|

|

MJ-12 |

12T/D |

2800*7100mm |

Batch |

|

|

MJ-15 |

13-15T/D |

2800*8000mm |

Batch |

|

|

MJL-15 |

15-16T/D |

2800*7100mm |

Semi-continuous |

|

|

MJL-20P |

30T/D |

1600*26000mm |

Fully continuous for plastics |

|

|

MJL-30T |

40T/D |

1600*26000mm |

Fully continuous for tires |

|

|

Accepted materials |

Waste tires/plastics, rubber/oil sludge/MSW/Medical Waste |

|||

|

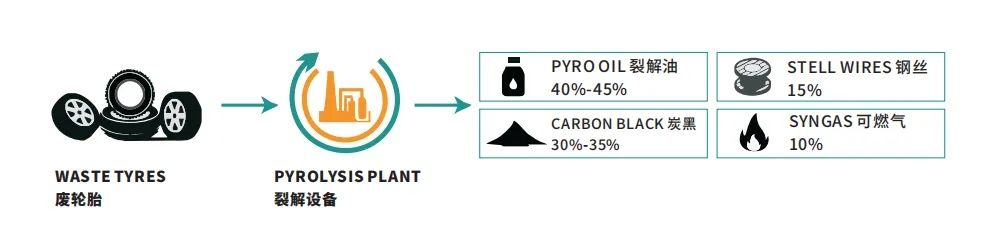

End products |

Pyrolysis oil, carbon black, steel wires , combustible gas |

|||

|

Applicable fuel |

Coal/natural gas/LPG/ Diesel/wood/pyrolysis oil |

|||

|

Thickness of Reactor |

16mm/18mm |

|||

|

Cooling |

Water Cooling |

|||

|

Land Required |

300-400m2 |

|||

Raw Materials

Final Products Application

1.Pyrolysis Oil (40-45%)

· Can be sold directly, widely used in ceramic factory, cement factory, steel factory, hotels, etc.

· Part of it can be used back to pyrolysis machine for heating the reactor.

· Can be refined to be non-standard diesel, can be used in the diesel generator, boat, and other heavy duty low speed diesel engines.

· Can be used directly in the heavy oil generator to get electricity.

2.Carbon Black (30-35%)

· Can be pressed to be briquettes and used as fuel .

· Can be further reprocessed to be higher quality, and used as fortifier and filler of plastic and rubber industry or as color master batch .

3.Steel Wires (13-15%)

· Can be sold directly

4.Combustible gas (7-10%)

· Will be recycled to the furnace for heating the reactor

Profit Analysis

|

DAILY RUNNING COST OF MLL-20P MODEL PYROLYSIS PLANT WITH SHREDDING AND BRIQUETTING SYSTEM |

|||||

|

Items |

Unit price |

Daily consumption |

Unit |

Total amount |

|

|

Raw material |

Plastics |

$50 |

30 |

Ton |

$1,500 |

|

Fuel |

Diesel , only used when start-up, in the normal operation, the main fuel will be syngas generated in the process |

$0.99 |

950 |

Liter |

$941 |

|

Electricity |

272KW, 24hours, in the constant opertation, the real consumption of the installed power is about 70% |

$0.17 |

4569.6 |

KWH |

$776.83 |

|

Labor |

$20 |

5 |

Person |

$100 |

|

|

Water |

$0.46 |

10 |

Ton |

$4.60 |

|

|

Others |

$20 |

||||

|

Total |

$3,341.93 |

||||

|

DAILY OUTPUT FROM PYROLYSIS PROCESS |

|||||

|

PYROLYSIS OIL (60%) |

CARBON BLACK (15%) |

SYNGAS (15%) |

WATER CONTENT (10% ) |

|

|

|

18 T |

4.5T |

RECYCLED TO THE FURNACE |

|||

|

DAILY RUNNING PROFIT FROM THE PROJECT |

|||||

|

Final Putput |

Unit Price |

Quantity (Ton) |

Unit |

Total Amount |

|

|

Carbon black |

$50.00 |

4.5 |

Ton |

$225.00 |

|

|

Pyrolysis oil |

$545.00 |

18 |

Ton |

$9,810.00 |

|

|

Total |

$10,035.00 |

||||

|

DAILY RUNNING PROFIT FROM THE PROJECT |

|||||

|

USD 10035-USD 3341.93=USD 6693.07 |

|||||

|

Remark: The Above data from Chinese market, customer can replace the date based on local market to get the real ROI |

|||||