Mingjie biomass carbonization equipment can produce biochar from agricultural waste through continuous pyrolysis technology. It not only processes waste but also generates high-value biochar products. Biochar from agricultural waste is one of the most direct and important ways to achieve negative carbon emissions. It locks waste carbon sources into a stable form, and when applied to soil, it further reduces greenhouse gas emissions.

The raw materials for preparing biochar are materials with high carbon content but low inorganic content. Rice straw, wheat straw, corn stalks, soybean roots, spent coffee grounds, sugarcane bagasse, rice husks, peanut shells, coconut shells, walnut shells, castor shells, corn cobs, olive pits, date pits, sunflower heads, and cottonseed are examples of agricultural wastes used to prepare biochar.

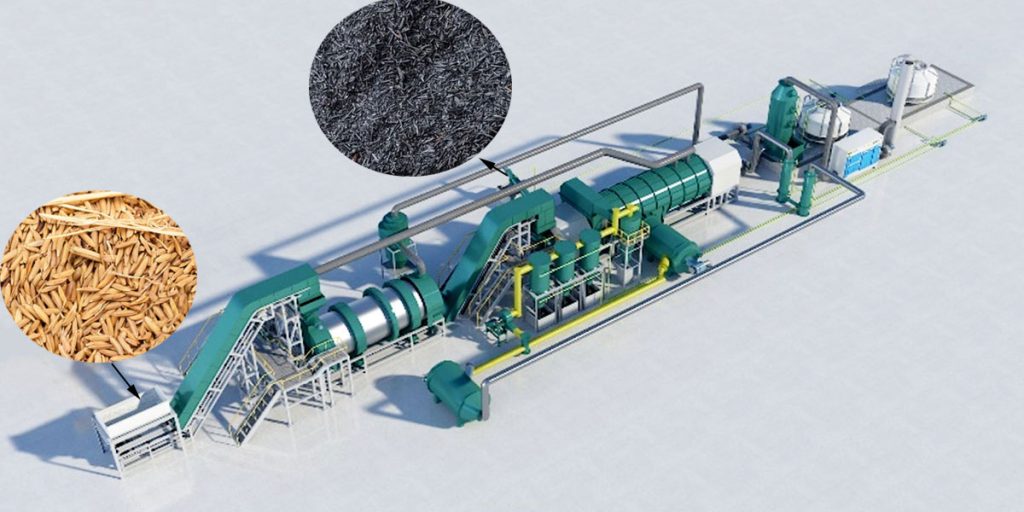

The pyrolysis of agricultural waste into biochar has reached commercial-scale application. Mingjie biomass pyrolysis plant utilizes continuous pyrolysis technology, enabling the continuous production of biochar. It can process a variety of agricultural waste, forestry waste, animal feces and sludge. This provides an economical and environmentally friendly conversion pathway for large quantities of waste biomass.

Mingjie biomass carbonization equipment has been applied to several projects that produce biochar from agricultural waste. These biomass pyrolysis projects have achieved significant results in terms of technological innovation and economic benefits.

MJT-1000 biomass pyrolysis equipment was used to produce rice husk biochar from agricultural waste. The rice husk biochar project not only recycles agricultural waste, but also creates environmental and economic value through stable carbon sequestration.

The high silicon content of rice husk biochar forms a more stable silicon-carbon structure, which is conducive to long-term carbon sequestration. Its structure can sequester carbon for hundreds to thousands of years.

The MJT-100 mobile biochar machine was used to process biomass pellets. The biomass pellet pyrolysis project first compresses loose biomass (such as straw) into high-density pellets, and then performs pyrolysis. This addresses the challenges of inconsistent biomass raw materials, high collection and transportation costs, and unstable pyrolysis conditions.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..