Practice has proven that slow pyrolysis is the optimal technology for producing rice husk biochar. Rice husk can be converted into high-value biochar through pyrolysis and carbonization. Rice husk biochar production equipment is the core of this conversion process.

For rice husks, their inherently high silicon content presents both a challenge and an opportunity. During the slow pyrolysis process, the silicon is retained and fixed within the biochar, making its structure more stable and its porosity more developed. However, this also places higher demands on the wear resistance of biomass pyrolysis equipment.

With the demand for large-scale rice husk biochar production, the capacity of pyrolysis carbonization equipment is a primary consideration. Large-scale production requires processing large quantities of rice husk raw materials per unit time to meet the growing market demand for rice husk biochar.

Continuous biomass carbonization plant is one type of equipment that can meet this high-capacity demand. Mingjie Group offers continuous biomass carbonization equipment in the following models: MJT-100, MJT-500, MJT-1000, MJT-2000, MJT-3000, and MJT-5000.

High-capacity pyrolysis carbonization equipment can quickly convert rice husks into biochar, giving it a competitive edge in the market. As the applications of rice husk biochar in soil improvement, biomass energy, and industrial raw materials continue to expand, market demand continues to rise. Insufficient rice husk biochar production equipment will not only fail to meet market demand, but will also extend production cycles and increase production costs.

The Mingjie continuous rice husk carbonization reactor boasts excellent stability in its structural design. It can withstand high temperatures, high pressures, and the impact of continuous material transportation. The rational design of the feed, discharge, and pyrolysis reaction areas ensures smooth material flow within the equipment, reducing blockages and jams. Optimized piping layout and connection methods ensure stable gas and material transmission, preventing leaks and pressure fluctuations.

The biochar production equipment utilizes high-quality, high-temperature and corrosion-resistant materials. It can withstand the demands of long-term high-temperature operation of the pyrolysis furnace. Components that come into direct contact with hot gases and materials, such as the reactor lining and piping, are made of 316 stainless steel.

The spiral blades of the continuous rice husk equipment's screw feeder and cooling and carbonizing unit are made of wear-resistant materials to withstand the friction and long-term material transportation. The fan, a key component providing gas power, features a high-quality, reliable impeller and bearings that directly impact the operational stability of the rice husk charcoal equipment.

The pyrolysis temperature has a decisive influence on the quality of rice husk biochar. Different pyrolysis temperatures produce significantly different properties. To achieve precise temperature control, pyrolysis carbonization equipment typically utilizes advanced temperature control technology.

A PLC controller precisely adjusts the power of the heating element according to a preset temperature curve, enabling precise control of the pyrolysis temperature with an accuracy of ±1°C. The temperature control range of rice husk biochar equipment typically ranges from 300°C to 800°C. This temperature range satisfies the specific requirements of rice husk biochar properties for different applications.

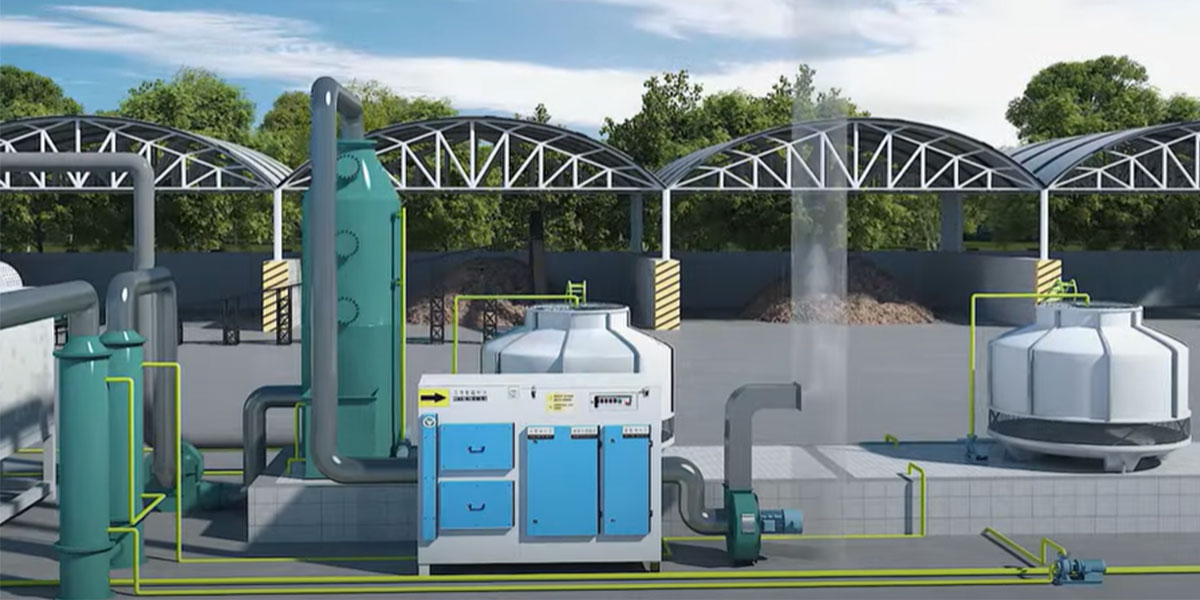

For large-scale rice husk biochar production, environmentally friendly pyrolysis carbonization equipment is an essential requirement for sustainable development. To achieve these standards, the pyrolysis carbonization equipment utilizes a series of advanced purification and syngas recycling technologies.

The continuous rice husk pyrolysis equipment excels in energy conservation by cleverly utilizing the combustible gases generated during the carbonization process for recirculating combustion.

By optimizing the combustion process and equipping it with efficient desulfurization, denitrification, and dust removal equipment, exhaust gas emissions meet emission standards. In terms of wastewater treatment, water resources are recycled, reducing wastewater discharge.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..