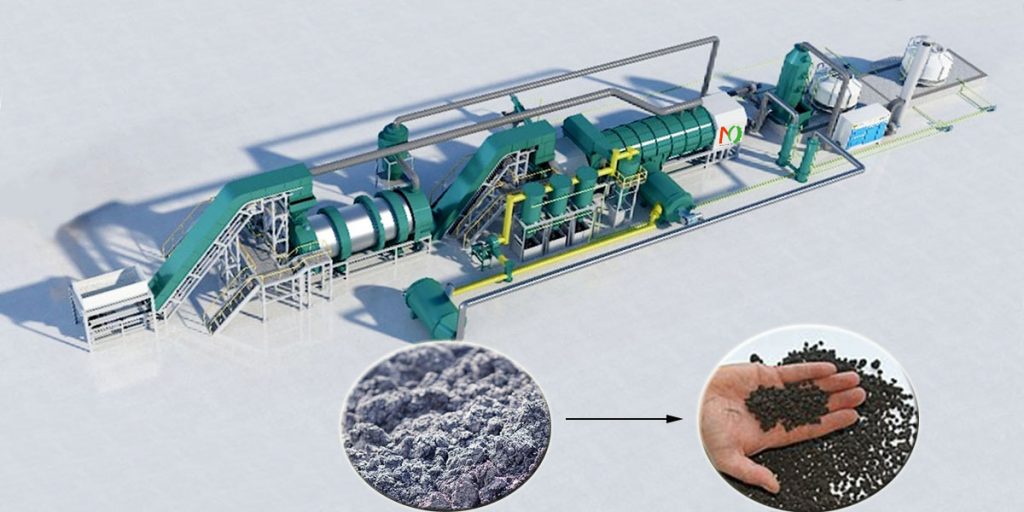

When applying pyrolysis technology to sewage sludge projects, the cost of the sludge pyrolysis plant is a significant issue. A sludge pyrolysis plant requires significant investment, encompassing a complete pyrolysis treatment system. This includes drying equipment, feed system, pyrolysis reactor, product separation equipment, and exhaust gas treatment equipment.

For some small sewage treatment plants or those in economically underdeveloped regions, the high cost of pyrolysis equipment can be a major barrier to the adoption of pyrolysis technology. The continuous sludge pyrolysis plant cost ranges from approximately $150,000 to $400,000 USD per daily ton of processing capacity. This means that a pyrolysis plant processing 100 tons of sludge per day could require an investment of between $15 million and $40 million USD.

The sludge pyrolysis plant also has relatively high operating costs, primarily encompassing energy consumption, raw material consumption, equipment maintenance, and labor costs.

In terms of energy consumption, the pyrolysis process requires a significant amount of heat energy to heat the sludge to the required temperature for pyrolysis, and this energy cost accounts for a significant portion of operating costs. Mingjie continuous biomass pyrolysis plant utilizes the waste heat generated during the pyrolysis process to dry and preheat the sludge. This not only reduces reliance on external energy sources and lowers energy costs, but also reduces carbon emissions.

Raw material consumption primarily involves auxiliary materials such as desiccants and adsorbents. While the individual costs are relatively low, they can accumulate significantly over time.

Equipment maintenance costs are also not negligible. Biomass pyrolysis equipment operates under harsh conditions such as high temperature and high pressure, making component wear and corrosion a concern. Regular maintenance and replacement are essential, increasing operating costs.

In terms of labor costs, the operation and management of pyrolysis equipment requires specialized technicians, resulting in relatively high labor costs.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..