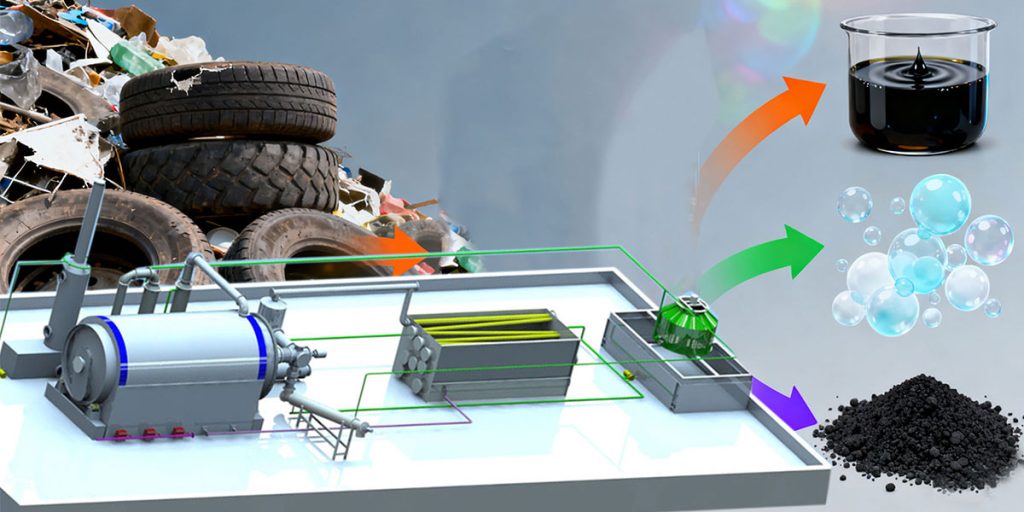

Faced with the surge in solid waste production and the severe pollution caused by traditional treatment methods, pyrolysis equipment has garnered significant attention as a green solution that turns waste into valuable resources. Solid waste pyrolysis equipment decomposes waste at high temperatures in an anaerobic or oxygen-deficient environment. It can convert organic matter into pyrolysis oil, syngas, and carbon black. This achieves both a waste volume reduction of over 80% and the production of high-value energy products.

Compared to traditional incineration, pyrolysis technology, as an endothermic process, can suppress dioxin formation at its source. Its heat utilization rate reaches 85%-90%. Economic benefits are three times higher than incineration, and it can treat various solid wastes. Including waste tires, rubber, plastics, oil sludge, municipal solid waste, and medical waste.

Solid waste pyrolysis equipment, with its unique advantages, has been widely used in numerous fields. It injects new vitality into the sustainable development of various industries.

In the field of municipal solid waste treatment, pyrolysis equipment plays a crucial role. It has become a powerful weapon to solve the problem of urban waste accumulation. During the pyrolysis process, the organic components in municipal solid waste are converted into syngas, pyrolysis oil and carbon black. These combustible gases can be directly used for power generation, while the pyrolysis oil can be further processed and utilized as a chemical raw material.

Compared with traditional landfill methods, pyrolysis treatment greatly reduces the amount of waste sent to landfills, alleviating the problem of land resource scarcity. Compared with incineration, pyrolysis produces significantly fewer harmful gases, reducing pollution to the atmospheric environment.

Industrial solid waste is diverse, complex in composition, and difficult to treat. Pyrolysis equipment offers a new approach to industrial solid waste treatment. The application of industrial solid waste pyrolysis equipment has expanded from waste tires, oil sludge to emerging complex solid wastes.

Driven by strong policy guidance and market forces, the pyrolysis and resource utilization of industrial solid waste, as a key component of the circular economy.

Pyrolysis equipment demonstrates numerous significant advantages in solving the challenges of solid waste treatment.

The environmental performance of pyrolysis equipment is particularly outstanding. During the pyrolysis process, because it takes place under anaerobic or hypoxic conditions, the emission of harmful gases is significantly reduced. The pyrolysis equipment is equipped with a flue gas purification system to effectively reduce the emission of harmful gases. This greatly reduces pollution to the atmospheric environment.

Resource recycling is another key advantage of pyrolysis equipment. The combustible gases, pyrolysis oil, and solid char in the pyrolysis products all have high economic value. Combustible gases can be directly used as fuel for power generation, heating, etc., supplementing energy gaps. Pyrolysis oil can be used as a chemical raw material for the production of plastics, rubber, and other products. Solid char can be used as an adsorbent, soil conditioner, etc.

Pyrolysis equipment also has a significant advantage in terms of land space. Compared to traditional landfills, pyrolysis equipment occupies a smaller area and does not require large amounts of land resources. Pyrolysis equipment can efficiently process solid waste in limited space. This alleviates the pressure on land resources and provides strong support for the sustainable development of cities.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..