The core technology of tire pyrolysis oil to diesel is pyrolysis. This is a process of decomposing organic matter by high temperature in an oxygen-free or low-oxygen environment. Mingjie Group provides pyrolysis plant and distillation plant to solve the problem of Tire Pyrolysis Oil To Diesel.

Our tire pyrolysis plant and pyrolysis oil distillation plant have been applied to solid waste pyrolysis projects in many countries, such as Malaysia, Peru, South Korea, Iraq, etc.

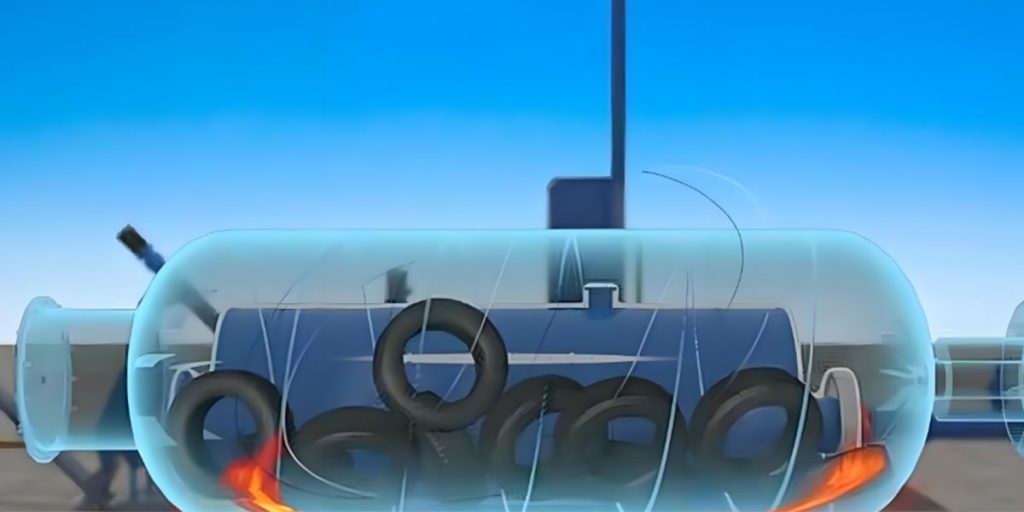

In the pyrolysis reactor, under high temperature and oxygen-deficient conditions, the chemical bonds between the molecules of organic matter such as rubber in the tire gradually break, and a complex decomposition reaction begins.

After the pyrolysis is completed, the oil and gas produced by the pyrolysis will enter the cooling system through the pipeline. In the condenser, the oil and gas are quickly cooled and condensed into a liquid, which is the tire pyrolysis oil.

In order to further obtain diesel, the tire pyrolysis oil needs to be refined by waste oil distillation plant. The refining process usually uses distillation and refining methods.

The tire pyrolysis oil distillation is to use the difference in boiling points to separate the various components in the pyrolysis oil from low to high in order. Thereby obtaining products of different fractions, including fractions with a boiling point close to that of diesel.

Pyrolysis oil refining is to treat the obtained crude diesel fraction to remove harmful impurities and improve its color, odor, stability, lubricity, corrosiveness and environmental protection indicators.

The tire pyrolysis oil to diesel project has made outstanding contributions in the field of environmental protection. It provides a "green key" to the problem of waste tire treatment.

Hundreds of millions of waste tires are produced every year around the world. If these tires are discarded or simply landfilled, they will not only occupy a large amount of valuable land resources, but also cause serious damage to soil structure and ecological environment.

The tire pyrolysis equipment has achieved the purpose of turning waste tires into energy. The organic components in the tires are converted into pyrolysis oil and other valuable products through the pyrolysis plant. This greatly reduces the pollution of waste tires to the environment and realizes the recycling of resources.

Compared with traditional fossil fuels, diesel produced from tire pyrolysis oil can significantly reduce carbon emissions and pollutant emissions during the combustion process. Studies have shown that the use of this diesel can reduce sulfur dioxide emissions by about 80%, nitrogen oxide emissions by about 30%, and particulate matter emissions by a large margin. It effectively reduces pollution to the atmospheric environment.

From the perspective of economic benefits, tire pyrolysis oil to diesel equipment creates considerable economic benefits by converting waste tires into valuable diesel and other products such as carbon black, steel wire, etc.

According to relevant data, for every 1 ton of waste tires processed, about 0.4-0.5 tons of tire pyrolysis oil can be produced. After being refined into diesel, it can bring considerable sales revenue according to the current market price.

At the same time, the carbon black from tire pyrolysis process can be widely used in rubber, plastic, ink and other industries, and has a high market value. The recycled steel wire can also re-enter the steel production field to realize the recycling of resources and further increase economic benefits.

The emergence of tire pyrolysis plant provides a relatively cheap energy option for the industrial and transportation sectors. Using this diesel from tire pyrolysis oil, enterprises can reduce fuel procurement costs, improve economic benefits, and enhance market competitiveness.

In addition, the development of tire pyrolysis projects has also driven the development of related industrial chains. For example, from the recycling of waste tires to the production and sales of tire pyrolysis oil to diesel.

The rise of tire pyrolysis plant has brought new hope for energy structure adjustment. This renewable energy source has opened up a new path for the energy field and is expected to become an important substitute for traditional fossil fuels.

In the adjustment of energy structure, tyre pyrolysis plant plays an important role. It not only enriches the types of energy, increases the stability and security of energy supply, but also promotes the energy industry to develop in a green and sustainable direction.

In some industrial fields with large energy demand (such as steel, cement, chemical industry, and transportation), diesel produced from tire pyrolysis oil can be used directly as fuel.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..