The waste tire recycling plant is an advanced solid waste recycling facility. It is designed to convert waste tyres into valuable resources through a pyrolysis process. These pyrolysis plants play a key role in addressing the global challenge of waste tire management.

According to statistics, more than 1.8 billion waste tyres are generated worldwide every year. Market reports show that the global tire pyrolysis recycling market is expected to reach $8.92 billion by 2029, with a compound annual growth rate of 3.7%. It is predicted that by 2034, the market will grow to $9.51 billion, with a compound annual growth rate of 5.6%. This highlights the continued growth of the waste tire recycling plant market, especially driven by recycled rubber and pyrolysis technology.

Australia and India are expanding tire recycling capacity, with plans to process truck tires and build new pyrolysis plants. Pyrolysis capacity in Europe is also increasing rapidly and is expected to reach 11% of global capacity by 2027.

High initial investment in waste tire pyrolysis plants, operating costs, complex regulations, and limited market acceptance of pyrolysis products remain major barriers. However, fully automated pyrolysis plants, pyrolysis oil as fuel, and carbon black pyrolysis products are addressing these issues.

Mingjie Group's solid waste pyrolysis plant and biomass carbonization plant projects have been widely used in more than 30 countries around the world. This demonstrates the maturity and commercial viability of its pyrolysis technology.

The core processes of a waste tire recycling plant include mechanical recycling, pyrolysis and distillation.

Mechanical recycling is a process of crushing, magnetic separation and grinding tires into rubber pellets or rubber powder.

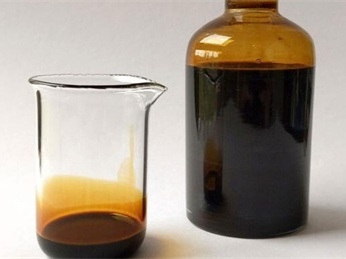

Tyre pyrolysis recycling is a thermal decomposition process that takes place in the absence of oxygen. The waste tire recycling plant breaks down tires into pyrolysis oil (40-45%), recycled carbon black (30-35%), steel (15%) and combustible gases (10%).

Pyrolysis oil and recycled carbon black are becoming increasingly popular in high-value industries. Europe pyrolysis capacity is expected to surge from 1.4% of global production to 11% by 2027. The price of pelletized recycled carbon black will decouple from virgin carbon black. Tire pyrolysis oil distillation plant can refine tire pyrolysis oil or waste engine oil into diesel or gasoline, making them reach a higher use value.

The waste tire recycling plants are evolving from waste management facilities to strategic nodes in the circular economy.

The pyrolysis plant uses pyrolysis technology to treat waste, including waste tires, plastics, medical waste, oil sludge, municipal solid waste, industrial solid waste, biomass, etc. Its core goal is to convert organic solid waste into high value-added products, such as pyrolysis oil, carbon black, gas, biochar, etc. At the same time, it reduces the environmental problems caused by landfill and incineration.

With breakthroughs in pyrolysis technology and policy support, pyrolysis plants are expected to transform tire waste into a $9.5 billion industry by 2034. The waste tyre recycling plants offer scalable solutions for environmental management and economic growth.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..