Tire pyrolytic carbon black (TPCB) is a black powder obtained by separating and purifying the solid residue from waste tires after pyrolysis at 500-800°C in an oxygen-free or low-oxygen environment. As one of the four core products of waste tire pyrolysis (carbon black, bio-oil, syngas, and steel wire), its carbon content typically ranges from 85% to 95%. It also retains the tire's original inorganic fillers (such as zinc oxide, calcium carbonate, and silica), with an ash content of 5% to 10%.

The carbon black from tyre pyrolysis is currently the most technologically mature and largest-volume pyrolytic carbon black product. Its core value lies in its dual environmental and economic benefits: addressing waste tire pollution while replacing traditional industrial carbon black.

The pyrolysis carbon black is not only a byproduct of waste tire processing, but also a key link between solid waste resource utilization and the rubber industry. Tire pyrolysis machine addresses the problem of black pollution, and the application of tire pyrolysis carbon black achieves a resource cycle. Tire pyrolysis projects offer both environmental and economic benefits.

The production of tire pyrolysis carbon black relies on a dedicated waste tire pyrolysis production line. The key challenge is to solve the two major challenges of tire component separation and carbon black purification.

The process for obtaining carbon black from waste tires is as follows: waste tire pretreatment → high-temperature pyrolysis → product multiphase separation → carbon black purification and modification → finished product packaging.

The general waste tire pyrolysis process is as follows: the waste tires are washed, sliced, or crushed, and then sent to the reactor for pyrolysis reaction. The gaseous products produced enter the condenser, thereby achieving oil and gas separation. The pyrolysis oil distillation equipment can separate the tire oil into gasoline fraction, diesel fraction, and heavy oil fraction.

In addition, the tire pyrolysis carbon black is discharged after cooling through the slag discharge system. The residual solids can be treated by magnetic separation to obtain steel wire and crude carbon black. The crude carbon black can be further processed to obtain activated carbon and carbon black.

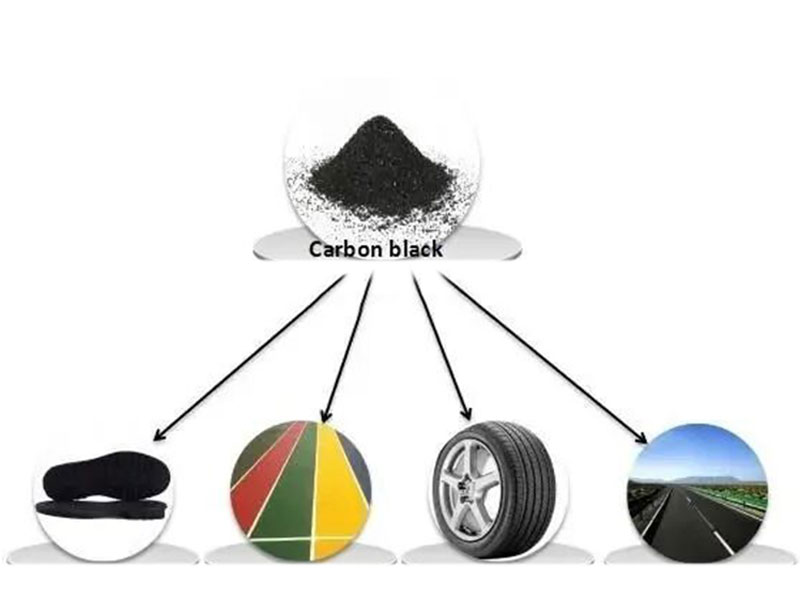

Statistics show that 89.5% of global carbon black consumption is used in the rubber industry, with tire carbon black accounting for 67.5%. Utilizing carbon black from tire pyrolysis has practical implications for the rubber industry, saving resources, protecting the environment, and reducing carbon emissions.

Scrap tire pyrolysis carbon black does not have the same reinforcing properties as traditional rubber carbon black. However, it can be used in various rubber products through adjustments to rubber formulations and processes. Scrap tire pyrolysis carbon black can be used in various component compounds, beyond those requiring high wear resistance in treads. For example, in the carcass, sidewall, and cord rubber of automobile tires, or as a partial replacement for traditional N660 carbon black for rubber.

Scrap tire pyrolytic carbon black, as a pigment black substitute, is primarily used in coatings, inks, and plastic masterbatches. Scrap tire pyrolysis carbon black colorants generally have a bluish hue, offering the advantage of enhanced high-color visual quality. Processing results in excellent usability and cost-effectiveness. Scrap tire pyrolysis carbon black can be used as a black pigment in the papermaking, dyeing, building materials, and concrete industries.

Adding scrap tire pyrolysis carbon black to asphalt improves its viscoelasticity, wear resistance, and strength, enhancing the performance of road pavement. The addition of carbon black from scrap tire pyrolysis to modified asphalt can overcome the high cost and limited application of traditional carbon black-modified asphalt.

Scrap tire pyrolysis carbon black, once modified and activated using specific methods, can be made into an industrial activated carbon alternative. Scrap tire pyrolysis carbon black can be activated using a variety of methods to produce activated carbon for industrial wastewater treatment.

Due to its unique conductive properties and excellent cost-effectiveness, conductive carbon black is widely used in various conductive materials and antistatic products. Due to its metal-bearing conductive properties, scrap tire pyrolysis carbon black may contribute to improved conductivity. After reprocessing and modification, scrap tire pyrolysis carbon black can serve as a conductive carbon black alternative.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..