Pyrolysis technology, as a highly efficient resource recycling and volume reduction technology, has a wide range of applications. Pyrolysis of solid waste, including plastics, rubber, and tyres, is the most mature application area in pyrolysis plants. Rubber pyrolysis machine has become a key tool for achieving efficient waste recycling, giving waste rubber new value.

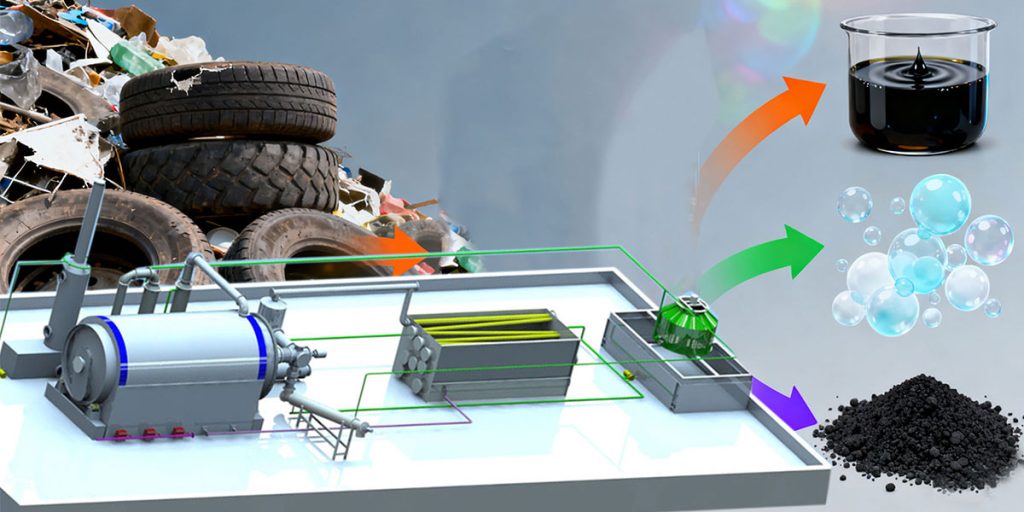

Rubber pyrolysis machine mainly consists of core components such as a pyrolysis reactor, a condenser, and a purification system.

The pyrolysis reactor typically employs a horizontal rotary furnace design. This allows for more uniform heating of the waste cables within the furnace, ensuring a complete and efficient pyrolysis reaction.

The condenser, closely connected to the pyrolysis reactor, plays a crucial role in cooling and liquefying the high-temperature oil and gas generated in the pyrolysis reactor.

The purification system ensures that the rubber pyrolysis process meets stringent environmental standards. It utilizes various advanced purification technologies, such as desulfurization towers, bag filters, and activated carbon adsorption.

Rubber pyrolysis equipments are widely used in various fields due to the diversity and practicality of their products. They serve as a crucial link between waste rubber and resource recycling.

Rubber pyrolysis machine is primarily used in environmental protection and solid waste treatment. It can process various types of waste rubber, including waste tires, rubber conveyor belts, rubber seals, and waste latex products.

They can specifically process waste rubber mixed with municipal solid waste or industrial solid waste, preventing the generation of toxic substances dioxins. Simultaneously, they enable resource recovery, improving the resource utilization rate of solid waste treatment.

The fuel oil produced by rubber pyrolysis has a calorific value of approximately 42-45 MJ/kg, similar to diesel fuel. It can be directly used for combustion heating in industrial boilers, heating furnaces, and other equipment, or further refined through distillation into diesel or gasoline.

The combustible gas produced by pyrolysis can be used as domestic fuel or industrial fuel, achieving cascaded energy utilization.

The recycled carbon black generated by pyrolysis can partially replace virgin carbon black in the production of tires, rubber seals, plastic pipes, and other products. This not only reduces raw material costs, but also decreases energy consumption and pollution emissions during the production of virgin carbon black.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..