The tire recycling pyrolysis plant is essential to reduce the burden on the environment and develop a market for sustainable materials. With technological innovation and policy support, the tyre recycling industry is expected to achieve significant growth. Pyrolysis plant is increasingly combined with renewable energy systems to offset operating costs. As the market for pyrolysis oil and carbon black expands, pyrolysis systems will gain more momentum.

Tyre recycling pyrolysis plant aims to solve the problem of waste tire management and convert waste tires into reusable resources. Common methods include mechanical recycling, pyrolysis and energy recovery. Countries such as the EU, the United States and China are introducing policies to promote waste tire recycling, as well as emerging technologies.

Mechanical recycling mainly uses crushers to shred tires and make them into rubber crumbs or powder. The rubber crumbs produced by mechanical recycling are used for asphalt, flooring, and steel is recycled into new products.

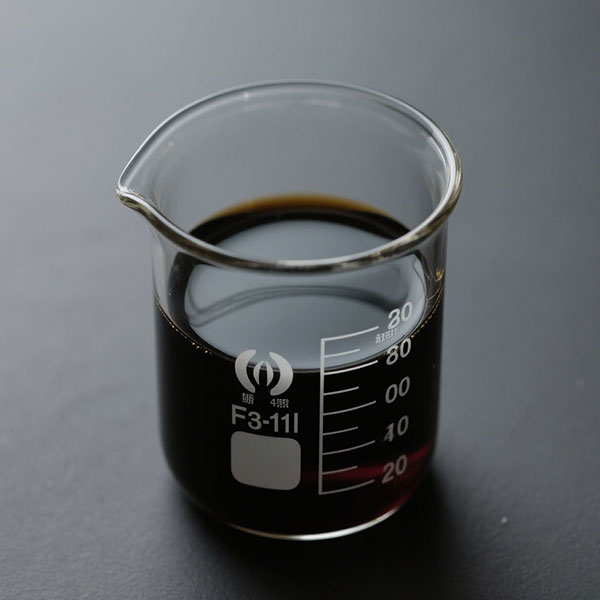

The tire recycling pyrolysis plant decomposes waste tires at high temperatures (450-900°C) in an oxygen-free environment. It converts tires into pyrolysis oil, carbon black, syngas and steel. Pyrolysis oil is being tested as a feedstock for sustainable aviation fuel (SAF) to meet global decarbonization goals.

Energy recovery is the use of tire incineration to generate heat or electricity. However, due to environmental concerns, this needs to be equipped with advanced emission control measures.

The non-condensable gas produced during the pyrolysis of waste tires contains a large amount of synthetic gases such as methane, hydrogen and carbon monoxide. Mingjie adopts a recycling system to recycle combustible gases, reduce the generation and emission of pollutants, and reduce energy consumption.

The non-condensable gas produced after pyrolysis of waste tires has a relatively high calorific value. Through recycling, the processing cost is greatly reduced. It does not require excessive investment in environmental protection equipment to achieve ultra-low emission standards. We use a special emission purification system to meet emission standards.

Mingjie Group is a professional tyre recycling pyrolysis plant manufacturer in China, providing perfect solutions for recycling waste tires, rubber, plastics and biomass. We are committed to providing a complete set of solutions for global companies to achieve the goals of harmless, resource-based and reduced solid and hazardous waste.

The pyrolysis plant for sale is used for MSW pyrolysis projects, waste tire recycling pyrolysis projects, waste plastic pyrolysis projects, medical waste pyrolysis projects, and biomass pyrolysis carbonization projects.

We have provided customized environmental protection solutions to more than 200 customers around the world and successfully implemented a number of large-scale pyrolysis projects in more than 30 countries.

The global tire recycling pyrolysis plant market is expected to grow at a CAGR of 4.5% between 2024 and 2030, driven by stricter environmental regulations and growing demand for sustainable materials.

Genan Group is the world's largest waste tire recycling company, operating four plants in Germany and Denmark with an annual processing capacity of more than 370,000 tons. Its technology breaks down tires into rubber particles, steel, which are used in artificial turf, road construction and other fields.

EU regulations: prohibit the use of rubber particles containing microplastics in sports venues and promote high value-added recycling. This provides good policy support for the development of pyrolysis plants. Mingjie pyrolysis plant for sale can convert plastics and tires into pyrolysis oil, carbon black and synthesis gas.

The United States recycles more than 80% of waste tires each year, of which 130 million are converted into tire-derived fuels to replace fossil fuels in cement plants.

Japan achieves high utilization rates through tire retreading (5%), recycled rubber powder (12%) and pyrolysis refining.

European Dutch companies use tyre recycling plant to convert tires into raw materials, such as pyrolysis oil and carbon black.

Henan, China has built the world's first smart green pyrolysis plant for waste tires. It processes 100,000 tons of tires annually, produces pyrolysis oil, carbon black and other products, and has an annual output value of $50,000,000. Its pyrolysis technology has attracted international attention. China has incorporated the processing of waste tires into the construction of "waste-free cities" with the goal of forming a trillion-level industrial chain.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..