Tyre recycling pyrolysis equipment is able to pyrolyze waste tyres that have reached the end of their service life. It converts waste tyres into reusable products – pyrolysis oil, carbon black, synthesis gas and steel wire through pyrolysis technology. This not only reduces the pollution of waste tyre to the environment, but also promotes the tyre recycling of resources.

Pyrolysis equipment provides a perfect solution to pollution, it can treat all waste tires/tyres. The pyrolysis plant has a high degree of comprehensive utilization, and can recycle the combustible gas formed by tyre pyrolysis. The tyre pyrolysis plant is equipped with safety and environmental protection system to achieve the smooth progress of the waste tyre recycling pyrolysis.

Countries around the world are extremely unbalanced in the construction of waste tyre recycling systems.

The EU has passed legislation requiring tyre manufacturers to be responsible for recycling. A full-chain recycling responsibility system has been established from manufacturers, distributors to consumers. And member states are required to increase the waste tyre recycling rate to 85% by 2025.

Japan has achieved a waste tyre recycling rate of over 95% through refined management. It has also forced companies to use tyre-derived fuel (TDF) and other methods to treat waste tires through the “zero landfill” policy.

However, in many developing and underdeveloped countries, the waste tire recycling system is almost blank. Tire recycling sites are scarce and lack unified planning and management.

There is a significant gap in the world in the field of waste tyre treatment technology. Developed countries have invested heavily in technology research and development, and cutting-edge technologies such as pyrolysis technology, microwave pyrolysis technology, and biodegradation technology are constantly emerging.

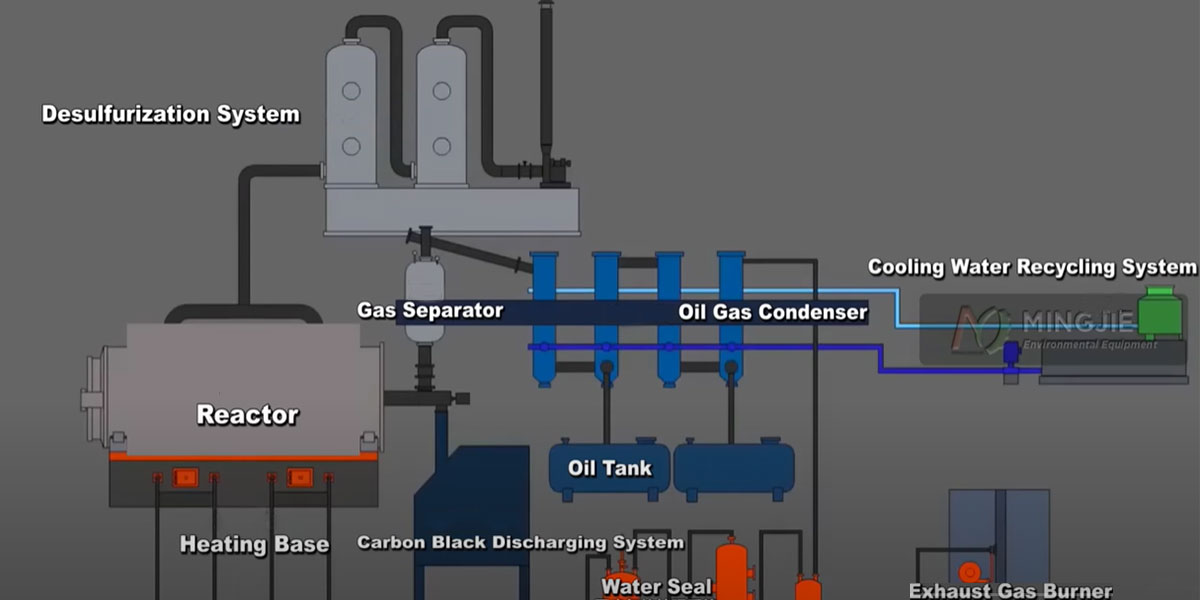

As one of the most promising methods for treating waste tyres, pyrolysis technology is gradually becoming the focus of industry attention. Its principle is to convert waste tyres into high-value products (pyrolysis oil, carbon black, steel wire and combustible gas) in a high-temperature, oxygen-free or low-oxygen environment.

During the pyrolysis process, waste tires are fed into the pyrolysis reactor and undergo thermal decomposition reactions at a high temperature of 450-650℃. Among them, organic components such as rubber will decompose into pyrolysis oil and combustible gas, while carbon black and steel wire will remain as solid products.

Each of these pyrolysis products has a wide range of uses and market demands. Pyrolysis oil has low viscosity and high calorific value. It can be used as fuel for industrial boilers, and can also be further processed to refine non-standard diesel. After secondary processing, carbon black can become an important raw material in the production of rubber products, electrode materials, composite materials, inks, asphalt modifiers, etc. Steel wire can be directly sent to steel mills for smelting. After the combustible gas is purified, it can provide heating fuel for the pyrolysis equipment and achieve energy self-sufficiency. Excess syngas can also be used for other industrial heating.

The advantage of the tire recycling pyrolysis plant is that it can turn waste tires into treasures and achieve efficient recycling of resources. It also has excellent environmental performance.

Compared with traditional landfill and incineration treatment methods, the tire recycling pyrolysis process produces almost no harmful gas and waste residue emissions, greatly reducing pollution to the environment. At the same time, the application of tire pyrolysis machine can also reduce dependence on fossil energy and has significant energy-saving and emission reduction effects.

At present, waste tire pyrolysis equipment has been more and more widely used and promoted at home and abroad. Mingjie pyrolysis plants for sale has been used in tire recycling pyrolysis projects in many countries, including Peru, Botswana, India, Lebanon, Egypt, South Africa, Philippines, Colombia, Australia, Thailand, Iraq, etc.

On April 24, 2025, South Korea first and largest waste tire pyrolysis plant was officially completed and is expected to be fully operational in May.

The tire pyrolysis plant built by the British company at the Port of Sunderland with an investment of US$129 million started construction in February 2025 and is expected to be put into operation in 2026. With an annual processing capacity of 10 million waste tires, it will become the largest facility of its kind in Europe. The tire pyrolysis project uses a closed-loop energy system, and the pyrolysis oil will be further refined into sustainable aviation fuel (SAF), and has received strategic investment from the International Airlines Group (IAG).

The Swedish company’s waste tire recycling pyrolysis plant in Uddevalla is expected to be put into operation in 2025. It processes 34,500 tons of waste tires annually, accounting for 40% of Sweden’s total. It mainly produces recycled carbon black and petroleum products.

The German company plans to build a new tire recycling pyrolysis plant that can process 20,000 tons of waste tires annually by the end of 2025. It uses continuous pyrolysis technology, and its products include carbon black and fuel oil.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..