Pyrolysis technology has become one of the important technologies in the field of medical waste treatment, because of its high efficiency, environmental protection and resource utilization. Pyrolysis medical waste treatment equipment achieves waste reduction, resource utilization and harmless treatment through thermochemical conversion of medical waste. It is of great significance to improve environmental quality and ensure public health safety.

The annual output of medical waste in the world has exceeded 20 million tons, with a growth rate of 17%-25% during the COVID-19 pandemic. The proportion of disposable protective equipment and testing consumables has increased significantly. Traditional incineration and landfill methods face secondary risks such as dioxin emissions and leachate pollution. The World Health Organization calls for the promotion of "no-incineration" treatment technology. Pyrolysis technology, as a new harmless technology, has ushered in development opportunities.

The medical waste pyrolysis equipment can decompose organic matter in medical waste in an anaerobic/anoxic environment (300-900℃). The pyrolysis products of medical waste include pyrolysis oil, syngas and carbon black. It can avoid the formation of dioxins, the pathogen inactivation rate is 99.99%, and the volume reduction rate exceeds 80%.

As an advanced waste treatment system, the effect evaluation of pyrolysis medical waste treatment equipment is crucial.

Significant Reduction Effect

The pyrolysis technology can achieve significant reduction effect by treating medical waste. During the treatment process, the medical waste undergoes high-temperature pyrolysis, and its volume is greatly reduced, which is conducive to subsequent treatment. At the same time, the pyrolysis process can also effectively remove pathogenic microorganisms and toxic and harmful substances in medical waste.

High Degree of Resource Utilization

During the pyrolysis medical waste treatment process, the organic matter in the waste is converted into pyrolysis oil and synthesis gas. They can be used as energy to realize the resource utilization of waste. This not only reduces the cost of waste treatment, but also realizes the recycling of energy.

Outstanding Environmental Friendliness

Pyrolysis medical waste disposal equipment is carried out in a high temperature and oxygen-deficient environment. This can effectively reduce the generation of toxic and harmful substances such as dioxins. At the same time, the gas produced by pyrolysis technology can further reduce pollutant emissions after purification.

High Treatment Efficiency

Pyrolysis technology has high efficiency in treating medical waste, and the treatment cycle is relatively short. Continuous pyrolysis plant can treat medical waste continuously and stably. In addition, pyrolysis medical waste treatment equipment has good adaptability to different types of medical waste.

The process flow of medical waste treatment equipment mainly includes pretreatment, pyrolysis, and emission purification treatment. The work process of the medical waste pyrolysis plant adopts closed, automated and intelligent control, which improves processing efficiency and reduces labor costs.

1. Pretreatment

Medical waste is pretreated before pyrolysis, mainly including classification, crushing, drying and screening. Medical waste of different properties are distinguished for subsequent treatment. And the medical waste is processed into granular materials suitable for pyrolysis system.

2. Pyrolysis of Medical Waste

The pre-treated medical waste is sent to the pyrolysis reactor, which is the core part of the pyrolysis gasification technology. In the pyrolysis machine, medical waste undergoes pyrolysis reaction in a high temperature and oxygen-free environment. In this process, the organic matter in the medical waste is decomposed at high temperature and converted into gaseous, liquid and solid products.

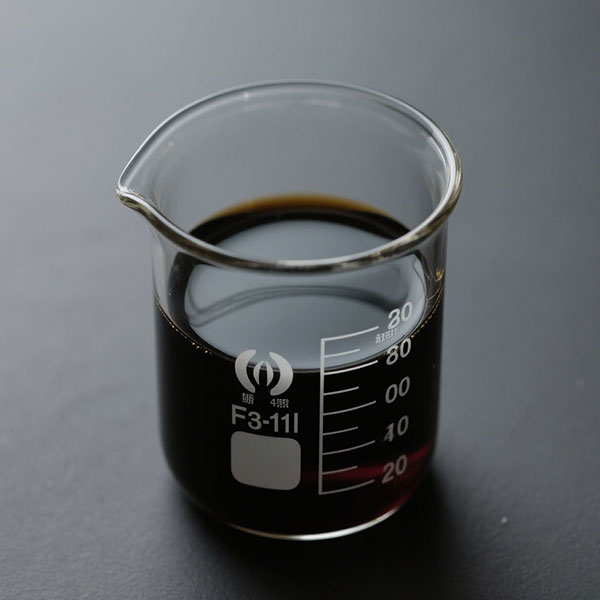

The gaseous products are mainly combustible gases, which can be used as energy. The liquid product is pyrolysis oil, which can be used as fuel oil or further refined by distillation plant. The solid product is mainly carbon black, which can be used as an industrial raw material.

3. Emission Purification Treatment

The tail gas produced during the pyrolysis process contains a small amount of pollutants, which needs to be purified. Tail gas purification treatment mainly includes dust removal, desulfurization, denitrification and other steps. This can ensure that the exhaust gas meets the emission standards.

The tail gas generated during the pyrolysis of medical waste is first subjected to dust removal to remove solid particles. Then, it enters the cooling system to reduce the temperature. The cooled tail gas then passes through a chemical scrubber to remove acidic or alkaline gases. For toxic and harmful substances in the tail gas, activated carbon adsorption or catalytic decomposition is used to further purify it.

Our medical waste treatment equipment adopts stainless steel materials, which have excellent high temperature resistance and chemical stability. They are able to prevent damage caused by corrosive components in the medical waste.

The application of medical waste pyrolysis projects is gradually expanding around the world. Pyrolysis equipment combines technological innovation with policy support to form a diversified medical waste treatment model.

China: Medical waste pyrolysis plants have been built in Xinjiang, Nanning, Wenzhou and other places, with medical waste treatment scales ranging from 0.5 T/D to 40 T/D.

Japan: Pyrolysis technology is gradually applied in the treatment of high-value plastic waste. For example, pyrolysis medical waste disposal equipment is used to treat plastic infusion tubes to achieve resource recovery.

Netherlands and France: Although incineration is the main method, pyrolysis technology is used as a supplement in specific scenarios (such as chemical waste treatment). For example, pyrolysis is used to treat drug-containing waste to reduce the risk of chemical residues.

United States: Develop small pyrolysis equipment for medical waste treatment in remote areas to reduce transportation costs and infection risks.

Africa: Batch pyrolysis plant helps local hospitals achieve harmless treatment of medical waste.

Southeast Asia: Thailand and Indonesia have introduced Chinese pyrolysis technology. They combine the high water content of local medical waste to optimize the pretreatment process and improve the efficiency of medical waste treatment.

According to Transparency Market Research, the global pyrolysis medical waste treatment equipment market will grow at a compound annual growth rate of 7.2% and reach US$4.5 billion in 2030. The Asia-Pacific region, including China and India, accounts for more than 60%.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..