The Plastic Pyrolysis Equipment Manufacturers occupy different shares in the market with their respective technical advantages, pyrolysis equipment characteristics and market strategies. The pyrolysis plant manufacturers produce plastic pyrolysis system through pyrolysis process.

At present, the Plastic To Fuel Pyrolysis Machine market is highly competitive, and the market structure is diversified. Globally, there are both internationally renowned large-scale environmental protection equipment manufacturers and many small and medium-sized enterprises focusing on the field of pyrolysis equipment.

Pyrolyze focuses on the research and development and production of efficient and environmentally friendly waste plastic pyrolysis equipment. Its products have the advantages of high pyrolysis efficiency and good product quality, and are widely used in industrial and commercial fields in many countries and regions.

In China, Henan Mingjie Environmental Protection Equipment Co., Ltd. is one of the important Plastic Pyrolysis Equipment Manufacturers in the waste pyrolysis industry. The company has long been committed to the research and development, production and sales of waste plastic pyrolysis equipment, and has a number of independent intellectual property rights and core technologies. The waste plastic to fuel pyrolysis equipment produced by Mingjie Group has the characteristics of large processing capacity, low energy consumption, and environmental protection standards, and is deeply favored by domestic customers.

Mingjie Company pays attention to product quality and after-sales service, and has established a complete sales and service network, which can provide customers with comprehensive technical support and solutions in a timely manner. In addition, Henan Mingjie Environmental Protection Equipment Co., Ltd. is also actively expanding the international market. Its products are exported to many countries and regions, such as Southeast Asia, Africa, and Europe, and are gradually emerging in the international market.

In addition to the above-mentioned companies, there are many other Pyrolysis Equipment Manufacturers in the market, such as Shredwell Recycling, Klean Industries, Hunan Benji Environmental Energy Technology Co., Ltd., Henan Doying Environmental Technology Co., Ltd., Beston Machinery Co., Ltd., Agile Process Chemicals LLP, and Jinhu Environmental Technology Co., Ltd.

These Plastic Pyrolysis Equipment Manufacturers have their own advantages in product performance, price, and service. They participate in market competition by continuously launching new products, optimizing product structure, and reducing costs.

It is responsible for conveying waste plastics into the pyrolysis machine.

To ensure the smooth progress of the pyrolysis process, the waste plastics usually need to be pretreated before feeding the fully continuous pyrolysis equipment. Pretreatment includes crushing, cleaning and drying.

However, batch pyrolysis plant does not require pretreatment of waste plastics.

It provides the required high temperature environment for the pyrolysis reaction. Common heating methods include fuel combustion heating and electric heating.

Fuel combustion heating generates high-temperature flue gas by burning natural gas, and uses the flue gas to heat the pyrolysis reactor. This method is relatively low in cost and suitable for large-scale pyrolysis production.

Electric heating converts electrical energy into thermal energy by means of resistance wire, electric induction, etc. It has a fast heating speed and precise temperature control. It is suitable for pyrolysis processes with high temperature requirements and relatively small scale.

As the core component of the pyrolysis reaction, the structure and material of the pyrolysis reactor have a crucial impact on the pyrolysis effect. The rotary kiln reactor rotates the cylinder to make the plastic tumble continuously in the kiln, and the heat is evenly distributed. It is suitable for processing waste plastics of different shapes and properties.

The pyrolysis reactor is usually made of high-temperature resistant and corrosion-resistant alloy steel to withstand the corrosion of high temperature and plastic decomposition products.

The waste plastic to fuel pyrolysis products (pyrolysis oil and pyrolysis gas) have a high temperature, and they need to be cooled by the cooling system.

The cooling system uses cooling water or air as a cooling medium to take away the heat of the pyrolysis products. The cooling system reduces its temperature, which is convenient for subsequent separation and collection. For pyrolysis gas, the cooling process can also condense some of its components into liquids to achieve gas-liquid separation.

After cooling, the pyrolysis product is a mixture of liquid (pyrolysis oil), gas (pyrolysis gas) and solid (carbon residue). They need to be separated into different components through a separation system.

For pyrolysis gas, it may also be necessary to further remove impurities and harmful gases such as hydrogen sulfide (H2S) and hydrogen chloride (HCl) through absorption, adsorption and other methods.

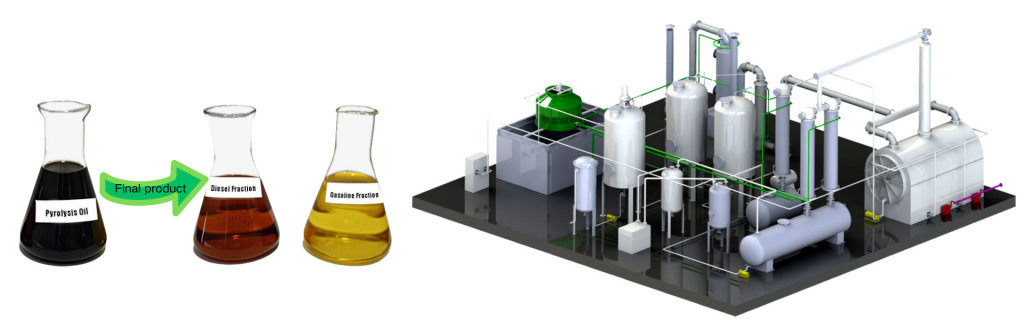

It is responsible for collecting separated products such as pyrolysis oil, pyrolysis gas and carbon residue. Pyrolysis oil is usually collected in oil storage tanks as fuel or further refined from Plastic Pyrolysis Oil To Diesel.

After purification, pyrolysis gas can be used as fuel gas for heating systems or other industrial production processes.

Carbon black can be used as an industrial raw material for the manufacture of activated carbon, building materials.

Pyrolysis Plant can convert a large amount of waste plastics into useful products such as fuel oil, pyrolysis gas and carbon black. It realizes the recycling of resources, reduces dependence on primary resources, and reduces production costs.

Plastic Pyrolysis Oil To Diesel Equipment is an efficient, environmentally friendly and energy-saving waste oil treatment equipment that can convert waste oil into diesel fuel. It makes the pyrolysis oil reach the standard of non-standard diesel through the process of distillation and purification.

With the increasing global attention to environmental protection and sustainable development, and the increasingly serious problem of plastic pollution, plastic to fuel pyrolysis machines have broad development prospects in the future. According to market research institutions, the global plastic to fuel pyrolysis equipment market will continue to expand in the next few years, and the annual compound growth rate is expected to remain at a high level.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..