In the process of actively exploring sustainable energy development and environmental protection around the world, biomass pyrolysis technology provides a very promising solution. Pyrolysis plants use continuous biomass carbonization process technology and are gradually replacing traditional carbonization furnaces.

From the perspective of energy, pyrolysis technology can convert abundant biomass resources into high-energy-density biochar, bio-oil and combustible gas. These products can be used as high-quality fuels in the fields of power generation and heating, effectively alleviating the pressure of energy shortage.

In terms of environmental protection, continuous biomass pyrolysis and carbonization technology is of great significance. On the one hand, it has found a proper way to deal with a large amount of biomass waste, avoiding the environmental pollution problems caused by traditional treatment methods (incineration and landfill).

Through pyrolysis and carbonization, these biomass wastes are converted into valuable energy products. Continuous pyrolysis and carbonization of biomass realizes the recycling of resources and reduces the burden of waste on the environment.

On the other hand, during the operation of biochar production equipment, reasonable process design and tail gas treatment system are adopted. This can effectively control the emission of pollutants and ensure the green and environmental protection of the biochar production process.

Based on the dual importance of biomass pyrolysis technology in the fields of energy and environmental protection, it is particularly necessary to deeply explore the biomass carbonization process.

This article will comprehensively and deeply analyze the continuous pyrolysis and carbonization process of biomass from multiple dimensions, including raw material pretreatment, pyrolysis and carbonization reaction principles, key process parameters, biomass carbonization equipment, and product applications.

In order to ensure the efficient and stable operation of the continuous pyrolysis and biomass carbonization process, raw materials pretreatment is an indispensable link. The pretreatment of biomass raw materials mainly includes crushing and drying steps.

The biomass raw materials are crushed into smaller particles by crushing equipment. Taking straw as an example, after crushing, its length is usually controlled between 5-20mm. This can significantly increase the specific surface area of the raw materials and improve the heat and mass transfer efficiency. In the pyrolysis reaction, smaller particles can absorb heat faster and accelerate the decomposition of internal organic components. The crushed raw materials are also more convenient during transportation and storage, which can reduce the accumulation and blockage of materials.

The moisture content of biomass raw materials is reduced to a suitable range through drying equipment, generally controlled between 10% and 15%. Excessive moisture content in biomass raw materials will have many adverse effects on the pyrolysis process.

For example, a large amount of heat is consumed for water evaporation, reducing the energy utilization efficiency of pyrolysis equipment. The water vapor produced by water evaporation may also dilute the pyrolysis gas, reduce the concentration of combustible gas, and affect its combustion performance. Excessive water may also increase the water content of bio-oil, reduce its stability, and make it difficult to store and transport.

Biomass pyrolysis refers to the process of heating biomass in a specific environment without oxygen or low oxygen to cause it to decompose and convert into charcoal, gas and liquid products. This process involves complex physical and chemical changes. The core is that the organic macromolecules inside the biomass break chemical bonds, decompose and reorganize under the action of thermal energy.

From a microscopic perspective, biomass is mainly composed of organic components, such as cellulose, hemicellulose and lignin. During the pyrolysis process, the first thing is that the water in the biomass evaporates at a lower temperature, creating conditions for subsequent pyrolysis reactions.

As the temperature rises, cellulose and hemicellulose begin to decompose, and their molecular chains gradually break to generate a series of low molecular weight compounds, such as volatile organic acids, alcohols, aldehydes and sugars. These substances further react to form the main components of bio-oil and combustible gas.

However, due to its complex structure and high stability, lignin has a relatively high decomposition temperature. In the later stage of pyrolysis, lignin gradually decomposes to form more solid charcoal and some aromatic compounds, which have an important impact on the structure and properties of biochar.

From the perspective of chemical reactions, the pyrolysis process includes multiple parallel and serial reactions. Dehydration reaction is one of the initial steps of pyrolysis. The water in the biomass is converted into water vapor under heating conditions and separated from the biomass. The pyrolysis reaction is the core reaction. Organic macromolecules decompose into charcoal, bio-oil and gas at high temperatures.

This process involves the breaking and reorganization of multiple chemical bonds. The reaction equation can be simply expressed as: biomass → charcoal + bio-oil + syngas. The tar cracking reaction is also an important part of the pyrolysis process. The tar produced by pyrolysis is further cracked at high temperatures to generate small molecular gases, such as methane and ethylene.

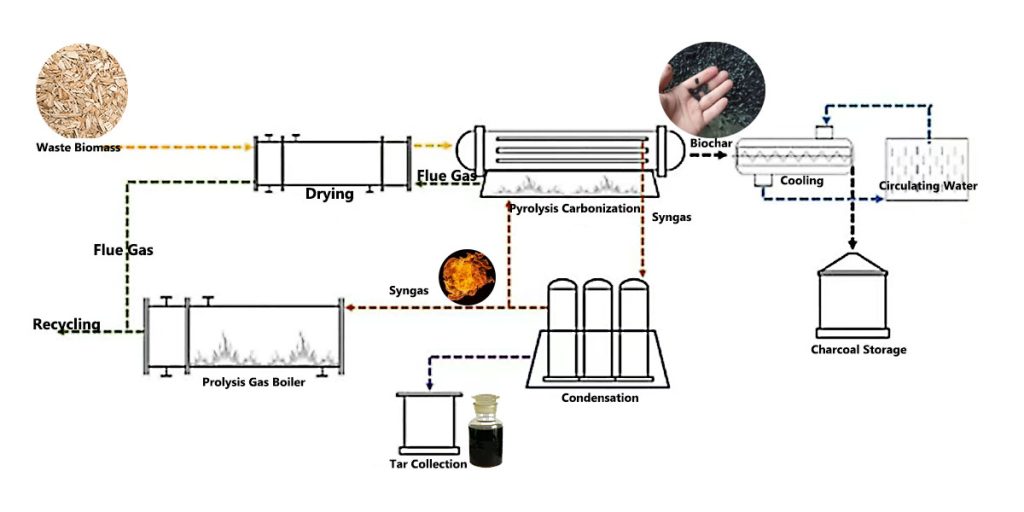

The biomass carbonization process can usually be divided into three key stages: drying, pyrolysis, and carbonization. Each stage has its own specific temperature range, reaction characteristics, and product changes.

Drying stage: The temperature range of this stage is generally 100-200°C. In this stage, the moisture in the biomass is the main reaction object. As the temperature gradually increases, the moisture inside the biomass begins to absorb heat, changes from liquid to gas, and gradually escapes in the form of water vapor.

This process is a physical change process, the main purpose of which is to remove moisture from the biomass and create favorable conditions for subsequent pyrolysis and carbonization reactions. During the drying stage, the mass of the biomass will gradually decrease, becoming drier and looser.

Pyrolysis stage: The temperature range of the pyrolysis stage is roughly 200-600°C, which is the most critical and complex stage in the charcoal making machine working process. When the temperature rises above 200°C, the organic components in the biomass begin to undergo violent chemical reactions. Hemicellulose decomposes first, and the glycosidic bonds in its molecular structure break to generate various volatile small molecular compounds, such as furfural, acetic acid, methanol, etc. These substances are important components of bio-oil and combustible gas.

As the temperature rises further, cellulose also begins to decompose. Its molecular chain gradually breaks to form glucose monomers and some oligomers, which further react to generate more bio-oil and gas. At this stage, the mass of biomass decreases rapidly and a large amount of volatiles are released. The reaction system is full of complex chemical reactions, including decomposition, recombination, polymerization, etc.

The bio-oil produced by Biomass Pyrolysis Machine contains rich organic compounds, such as phenols, alcohols, esters, etc. It has a high energy density and is a potential liquid fuel. The combustible gases produced mainly include hydrogen, carbon monoxide, methane, etc., which can be used as fuel for power generation, heating and other fields.

Carbonization stage: The temperature in the carbonization stage is generally above 600°C. After the pyrolysis stage, the remaining solid matter is mainly charcoal and some inorganic substances that are difficult to decompose. At high temperatures, these solid substances further undergo carbonization reactions, the residual volatiles continue to precipitate, and the structure of the charcoal gradually becomes denser and more stable. At this time, the fixed carbon content in the charcoal continues to increase, the ash content is relatively increased, and the pore structure of the biochar is gradually formed and improved.

The biomass carbonization process at high temperatures will also change the chemical properties of the biochar surface, increasing its adsorption performance and reaction activity. The biochar generated by Biochar Making Machine has a high carbon content and calorific value, and can be used as a high-quality solid fuel for industrial production and heating. At the same time, due to its good adsorption performance and pore structure, biochar can also be used in soil improvement, sewage treatment, activated carbon preparation and other fields.

In the process of continuous biomass pyrolysis carbonization, the performance of the biochar production equipment directly determines the efficiency, product quality and production cost of pyrolysis carbonization.

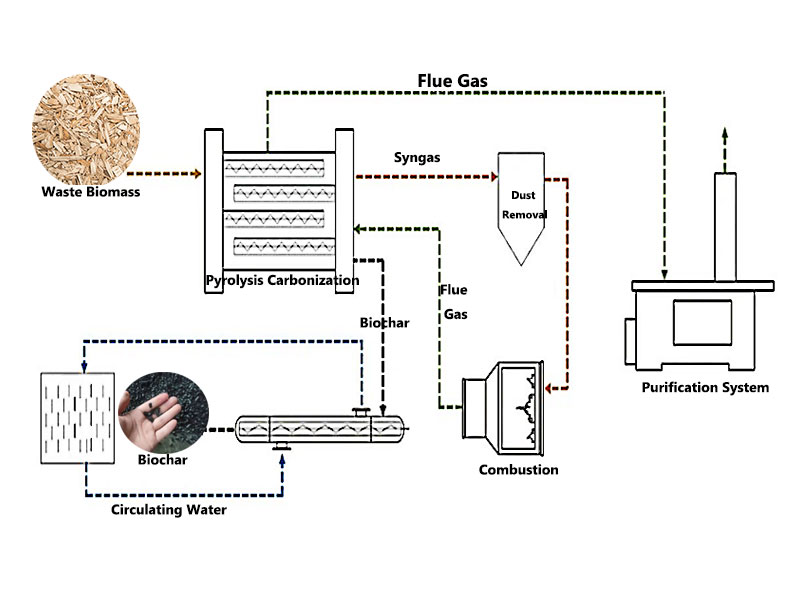

Mingjie Biomass Carbonization Plant uses continuous biomass carbonization process to convert wood and agricultural waste into biochar. This biomass continuous pyrolysis plant includes a pyrolysis carbonization core system, an intelligent control system, and an energy closed-loop utilization system. It is mainly composed of a feeding system, a carbonization reactor, a discharging system, a cooling system and a dust removal system.

It also adopts heat recovery technology to recover the heat generated in the carbonization process for preheating raw materials, greatly improving the comprehensive utilization efficiency of energy. At the same time, it is equipped with an efficient flue gas purification system to reduce the emission of harmful gases and particulate matter.

The continuous biomass carbonization plant can be used for efficient carbonization of various types of solid waste, such as straw, wood, straw, coconut shells, rice husks, sludge, livestock and poultry manure, and obtain high value-added biochar products. The continuous biochar production equipment has significant ecological advantages and economic benefits.

In the agricultural field, the product of continuous pyrolysis carbonization of biomass, biochar, plays an important role in soil improvement. Biochar has rich pore structure and large specific surface area. It can increase the air permeability and water retention of the soil, improve the soil structure, and create a good soil environment for the growth of crops.

At the same time, the surface of biochar carries an electric charge, which can adsorb nutrient ions in the soil, such as nitrogen, phosphorus, potassium, etc., reduce the loss of nutrients, improve soil fertility, promote the growth and development of crops, and increase the yield and quality of crops.

Biochar also has the ability to adsorb heavy metals and organic pollutants in the soil, which can reduce the harm of these harmful substances to crops, ensure the quality and safety of agricultural products, and realize the sustainable use of soil.

In the energy field, biomass continuous pyrolysis carbonization technology has opened up new ways for the development and utilization of renewable energy. The synthesis gas produced by pyrolysis carbonization is a high-quality energy product. The main components of synthesis gas include hydrogen, carbon monoxide, methane and other combustible gases. It can be used for power generation, heating, etc.

In the field of environmental protection, pyrolysis technology is of great significance for solid waste treatment and resource recycling. Through pyrolysis carbonization, a large amount of biomass waste has been effectively treated and utilized. At the same time, it also avoids the environmental pollution problems caused by traditional treatment methods (such as incineration and landfill).

The organic components in biomass waste are converted into valuable products such as biochar, bio-oil and pyrolysis gas, realizing the recycling of resources and reducing the burden of waste on the environment. The tail gas generated during the pyrolysis carbonization of biomass is purified and discharged in compliance with the standards. It reduces the emission of pollutants and plays a positive role in environmental protection.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..