The core of large-scale coffee grounds charcoal production equipment lies in continuity, automation, scalability, energy efficiency and environmental compliance. It is a complete large-scale production line that integrates a complex system of pre-treatment, pyrolysis, post-treatment, energy recovery and pollution control.

This is the first critical step in a large-scale production line, directly determining the efficiency and product quality of the subsequent pyrolysis process.

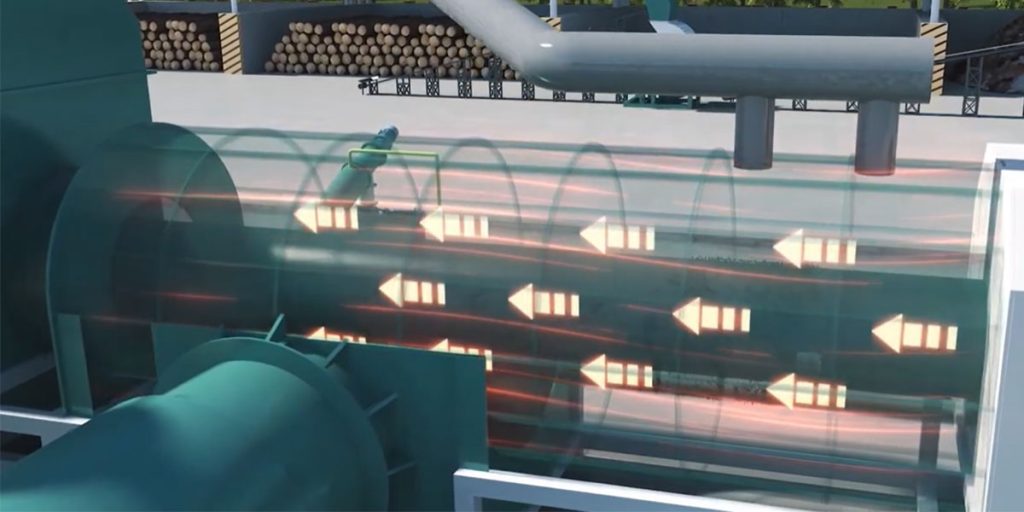

Dryer: This is a standard feature of large-scale coffee grounds charcoal production lines. It uses hot air (waste heat generated in pyrolysis process) to continuously and evenly dry the coffee grounds.

The drying process requires reducing the moisture content of the coffee grounds to below 10%-15%. Temperature control is also required to prevent premature decomposition of organic matter.

Conveyor System: A belt conveyor steadily and continuously feeds the dried coffee grounds into the main pyrolysis furnace.

Pyrolysis reactor is the core equipment for coffee grounds charcoal making machine. Large-scale continuous pyrolysis reactors primarily utilize a rotary kiln. This is a long, slightly inclined, slowly rotating cylinder. Coffee grounds enter at the upper end and are continuously lifted and dispersed by the rotation, moving toward the lower end. Heat is supplied from either an external or internal source.

Mingjie biomass to biochar production line offers a large waste coffee grounds processing capacity, simple operation, continuous operation, and excellent material adaptability.

Biomass carbonization equipment subjects pretreated coffee grounds to high-temperature pyrolysis in an oxygen-free or low-oxygen environment. By precisely controlling the heating rate and holding time, it gradually separates water, volatile organic compounds, and oils. The remaining solid product is coffee grounds charcoal.

Solid Product (Biochar): The pyrolyzed char is discharged from the reactor outlet and enters a spiral water cooler. After cooling, it is packaged to prevent air from entering the system.

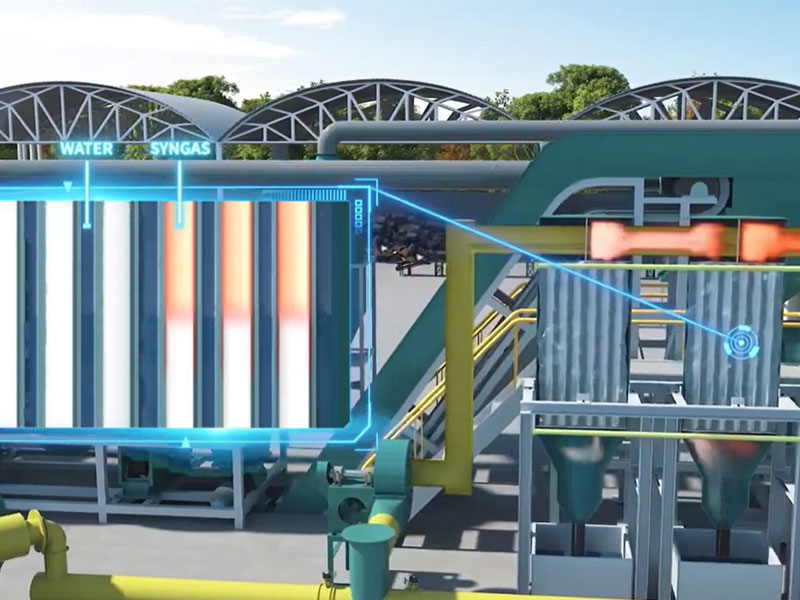

Gaseous Product: Synthesis gas first passes through a cyclone separator to remove large carbon dust particles carried by the gas.

The hot gas then enters a condenser, where condensable vapors are condensed into bio-oil, which is then collected.

Oil-Water Separator: The condensed product is typically a mixture of bio-oil and water, which requires separation.

Gas Purification System: After the bio-oil is separated, the synthesis gas (primarily containing CO, H₂, CH₄, etc.) undergoes further purification (such as dust removal and tar removal). It is then transported to the combustion chamber for use as energy.

The economic viability of a large-scale coffee grounds charcoal production line depends largely on this system.

The purified synthesis gas has a high calorific value and serves as the energy source for the carbonization furnace. Combustion provides heat for the dryer. The continuous pyrolysis system meets its drying and pyrolysis energy needs by burning its own syngas. This makes it energy self-sufficient and significantly reduces operating costs.

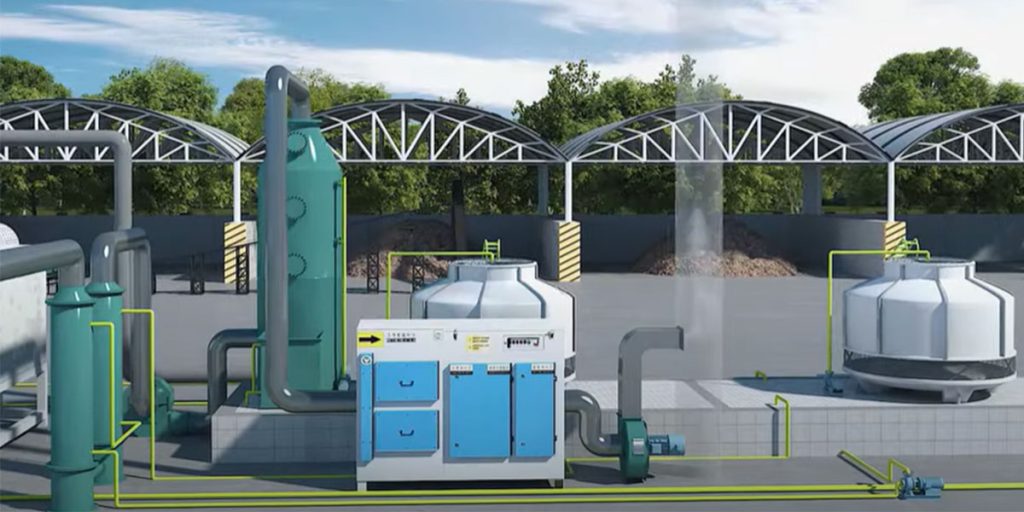

Even if most of the exhaust gas is recycled, a small amount of exhaust gas will still need to be discharged.

The secondary combustion chamber ensures complete combustion of combustible components in the exhaust gas.

The exhaust gas treatment unit may include desulfurization, denitrification (SCR/SNCR) equipment, and bag filters to ensure that emissions of SO₂, NOx, and dust meet strict environmental standards.

Coffee grounds offer unique advantages as a biochar feedstock:

The biochar from coffee ground is a porous carbon material, it is made from waste coffee grounds through pyrolysis (high-temperature, oxygen-deficient cracking). It possesses a high specific surface area, abundant surface functional groups, and a stable carbon structure. Coffee grounds charcoal is widely used in environmental remediation, agricultural improvement, energy storage, and other fields.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..