Plastic poses a threat to the environment because it cannot be biodegraded. But it also has the potential to become an important resource for the production of alternative energy sources, thereby creating an untapped market worth billions of dollars. Pyrolysis plant can realize plastic to fuel pyrolysis, convert non-biodegradable plastics into pyrolysis oil, carbon black and syngas.

Compared with traditional recycling methods, pyrolysis is more popular because its processing is simpler and more flexible. Unlike recycling, pyrolysis does not cause water pollution problems. It is regarded as a green technology.

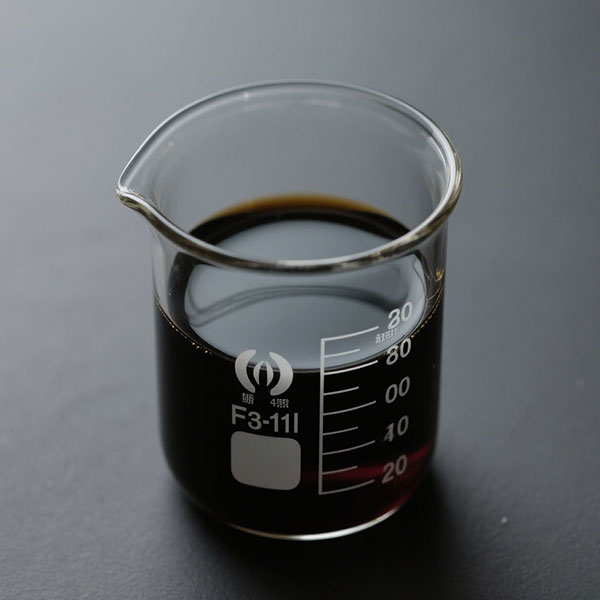

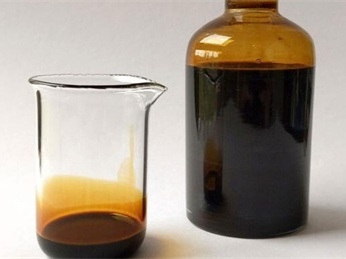

The fuel oil produced by plastic pyrolysis plant can be used in various applications, including furnaces, boilers, generators and diesel engines. Syngas has a very high calorific value and can be recycled to meet the energy demands of pyrolysis plants.

Plastic is a complex organic compound, mainly derived from hydrocarbons in petroleum-based components. The rapid production of plastic can be attributed to its unique properties. Every year, the amount of plastic transported globally is as high as approximately 280 million tons, which eventually inevitably becomes waste.

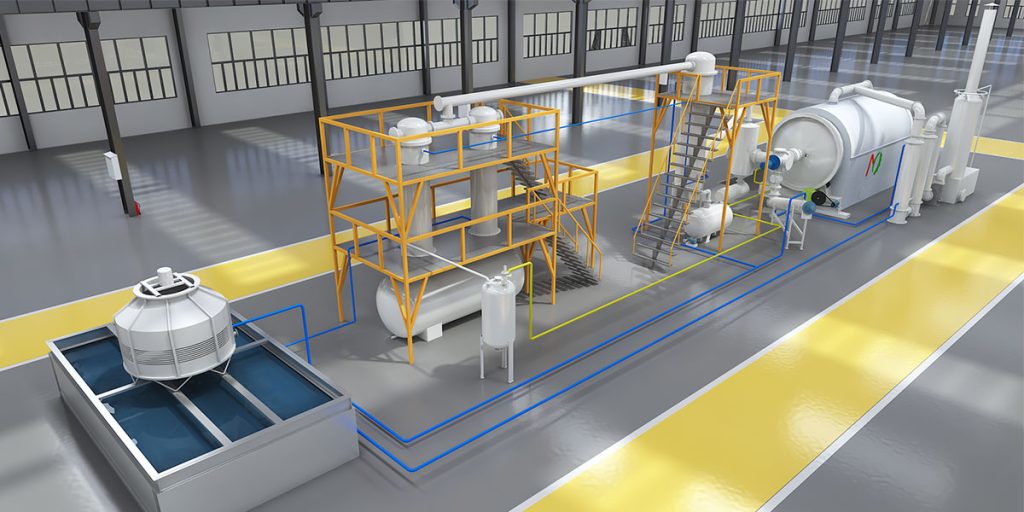

The increasing demand for plastic products has triggered many waste management challenges. Pyrolysis plants are the core equipment for converting waste plastics into high-value chemicals and fuels.

Thermoplastic Plastics can be softened and reshaped when heated. Common types of thermoplastics include include PE, PP, PVC, PS and PET. Pyrolysis system is a feasible strategy for recovering energy from plastic waste. It converts waste materials into energy-rich liquid and gaseous products. Plastic pyrolysis is the process of using heat to break down long-chain polymer molecules into smaller parts.

Polyethylene (PE) has good chemical resistance and electrical insulation, with a low density (0.91-0.96g /cm³), but its high-temperature resistance is relatively poor (melting point approximately 105-137℃).

PE classification: Low-density polyethylene (LDPE) is soft and transparent, and is used for films. High-density polyethylene (HDPE) has high rigidity and is used for pipes and containers. The main applications of PE include plastic bags, agricultural films, beverage bottles, pipes, etc.

How to Convert Waste Plastic to Fuel? PE plastic to fuel pyrolysis is usually carried out at 400-600℃, with the specific temperature depending on the type of raw material (LDPE, HDPE) and the target product. During the pyrolysis process, the PE molecular chains are broken by free radicals to generate small-molecule hydrocarbons. The main products include liquid pyrolysis oil, syngas and solid carbon black.

The Polypropylene (PP) characteristics are high temperature resistance (melting point 160-175℃) and good fatigue resistance, but it is prone to brittleness at low temperatures. It is mainly applied in food packaging, auto parts and medical devices.

The PP plastic to fuel pyrolysis mainly generates pyrolysis oil and synthetic gases (ethylene, propylene), with an oil yield of over 80%.

Polystyrene (PS) is characterized by excellent transparency and high hardness, but it is brittle. The glass transition temperature is approximately 90-100℃.

It mainly includes GPPS for transparent containers, HIPS for home appliance shells, and EPS for insulation materials and packaging. PS plastic is mainly used in disposable tableware, electronic product shells and building insulation boards.

The PS plastic to fuel pyrolysis generates styrene monomers and oligomers, which can be directly recycled for the production of new PS.

Polyvinyl chloride (PVC) is characterized by its flame retardancy and resistance to acid and alkali corrosion. However, it has poor thermal stability and stabilizers need to be added. It is mainly applied to building pipes, wire and cable sheaths, plastic doors and Windows, and medical pipes.

Polyethylene terephthalate (PET) is characterized by high strength, impact resistance, good transparency, and a melting point of approximately 245-260℃. It is mainly applied to beverage bottles, fibers and films.

The PVC plastic to fuel pyrolysis will release HCl gas and chlorine-containing organic compounds, which require additional treatment to avoid pollution and the pyrolysis is rather difficult.

The pyrolysis products of PET are mainly in gaseous form and are suitable for the production of syngas (CO, H₂). PET pyrolysis fuel oil is not recommended.

The improvement of Mingjie's pyrolysis technology and the optimization of the process have made the quality of the plastic pyrolysis fuel oil extremely excellent. In addition, the produced gaseous fuel has a high calorific value and is suitable for meeting the energy demands of the pyrolysis plant itself.

The plastic to fuel pyrolysis process generates various products, such as gas, oil/wax and heat. Its composition and output are determined by the type of plastic, reactor type and process conditions. Our technology worker will customize pyrolysis plant based on the characteristics of the raw materials. Our batch pyrolysis plant is equipped with dewaxing device to effectively avoid pipe clogging problems during plastic processing.

Our plastic to fuel pyrolysis plant has been applied to solid waste pyrolysis projects in many countries, such as Malaysia, Thailand, India, Australia, etc. Plastic waste can be effectively treated through pyrolysis to generate valuable alternative fuel sources. The pyrolysis of plastic waste can produce high-performance fuel oil, reduce reliance on fossil fuels, and solve the problem of plastic waste treatment at the same time.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..