Due to its high efficiency, pyrolysis technology currently dominates the field of plastic into fuel oil. By 2025, pyrolysis will account for approximately 40.6% of the plastic to fuel market share. The core principle of plastic into fuel is pyrolysis technology. As a typical chemical recycling method, it is becoming an important solution connecting waste management and energy utilization.

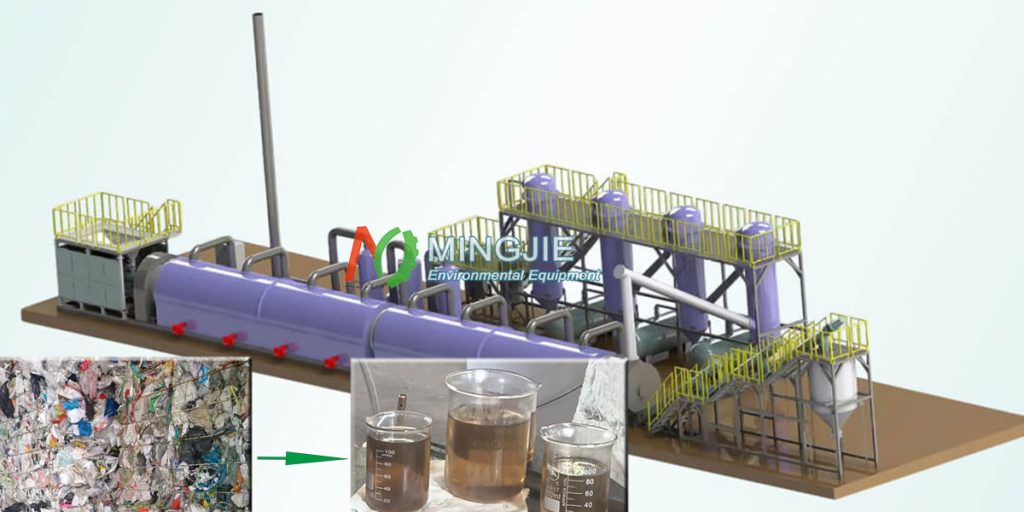

Mingjie pyrolysis plant is particularly suitable for processing plastics that are difficult to recycle mechanically, such as PP, PE, PS, composite plastics, and film plastics. It can be used for the resource utilization of low-value waste plastics, marine waste plastics, and medical waste plastics.

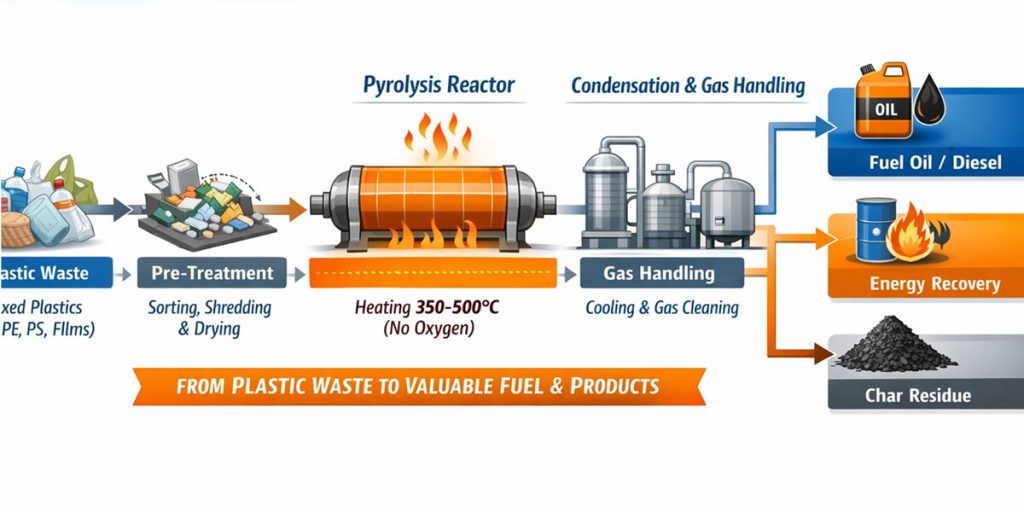

Plastic pyrolysis plant heats plastic waste in an oxygen-free or low-oxygen environment, converting it into pyrolysis oil fuel, syngas, and carbon black. Plastic pyrolysis oil or plastic-derived oil (PDO) is similar to crude oil. Pyrolysis oil can be further fractionated to obtain different fractions, such as gasoline and diesel.

Turning plastic into fuel supports the principles of a circular economy by reducing plastic waste in landfills and decreasing reliance on fossil fuels. With increasing plastic pollution and rising energy demands, plastic pyrolysis plant offers a sustainable solution. It can meet environmental regulations and supports the transition to renewable energy.

According to research institutions, the global plastic to fuel oil market is entering a period of rapid growth. Turning plastic to fuel oil not only provides an effective solution to the plastic waste problem, but also creates a new emerging market with enormous commercial potential. With the continuous maturation of pyrolysis technology and the gradual release of market demand, the scale of the plastic to fuel oil market continues to expand.

The plastic to oil machines have gradually progressed from laboratory or small-scale demonstrations to industrial-scale facilities. Energy giants, leading chemical companies, and local innovators are collaborating to expand market and technological applications. The industrialization of plastic pyrolysis is being pursued in North America, Europe, Asia, and developing regions.

Its commercialization process is primarily driven by the following three factors:

Mandatory policies and regulations: The EU's plastic tax, the "extended producer responsibility" schemes in many countries, and landfill bans legally mandate companies to handle plastic waste. This creates a strong demand for the plastic-to-fuel market.

Strategic investments by leading companies: Oil giants (such as Shell, BP, and TotalEnergies) and chemical giants (such as BASF and Dow) are actively investing in, collaborating on, or acquiring relevant technologies. Their aim is to gain a competitive advantage in raw materials in the circular economy era.

Clear carbon reduction benefits: Compared to traditional incineration or the production of virgin fuels, plastic-derived fuels have been proven to significantly reduce carbon footprint. This gives plastic pyrolysis plant added value in carbon trading and green certification systems.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..