Waste plastic pyrolysis recycling is an effective means of treating waste plastics through pyrolysis equipment. Plastic pyrolysis equipment converts waste plastics into high-value products under high temperature and oxygen-free conditions. It provides an effective way to solve plastic pollution and recycle resources.

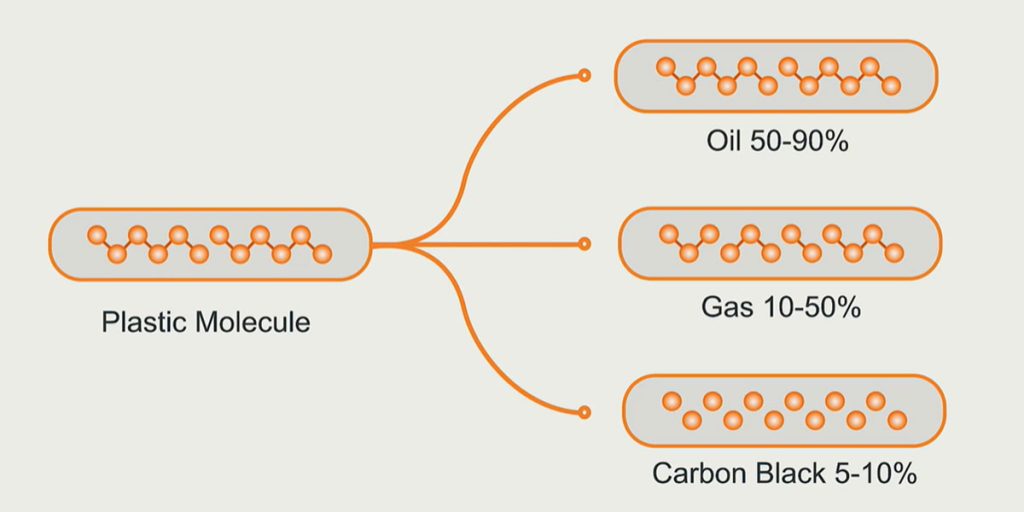

Plastics are composed of high molecular polymers, which are connected by chemical bonds to form long chain structures. The principle of waste plastic pyrolysis recycling is to apply high temperature to waste plastics in an oxygen-deficient or low-oxygen environment.

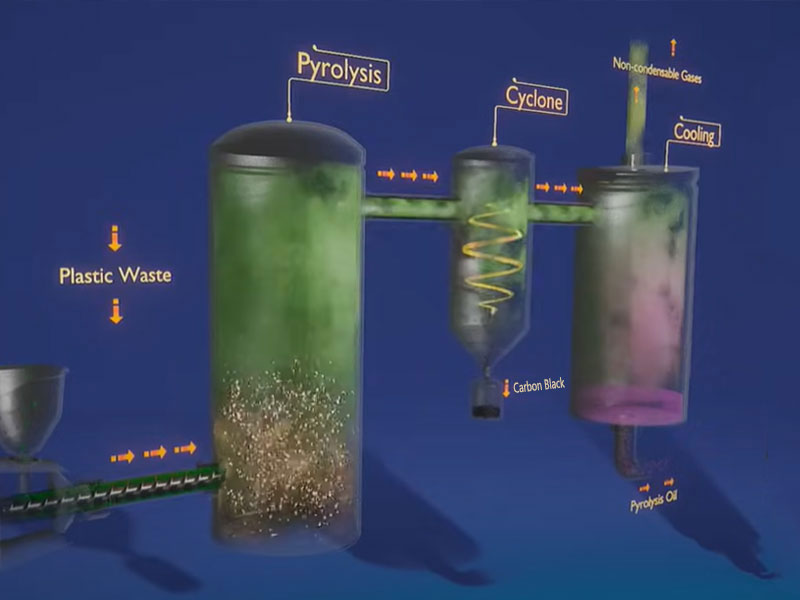

The pyrolysis plant is the core equipment for recycling waste plastics. During the plastic waste pyrolysis recycling process, the pretreated waste plastics are fed into the pyrolysis reactor. In an oxygen-free or low-oxygen environment, the waste plastics are heated to a specific temperature range by external heating. Under this high temperature condition, the chemical bonds in the plastic molecules are broken, and the high-molecular polymers are gradually decomposed into low-molecular compounds.

The plastic pyrolysis equipment is heated to 300℃-800℃, the chemical bonds within the plastic molecules are broken, and the original long-chain macromolecules are broken into relatively small molecular fragments. These small molecular fragments exist in the form of gas, liquid oil and solid carbon black.

The pyrolysis plastic plant separates the oil and gas through the condensation system and purification system, and converts them into pyrolysis oil and synthesis gas.

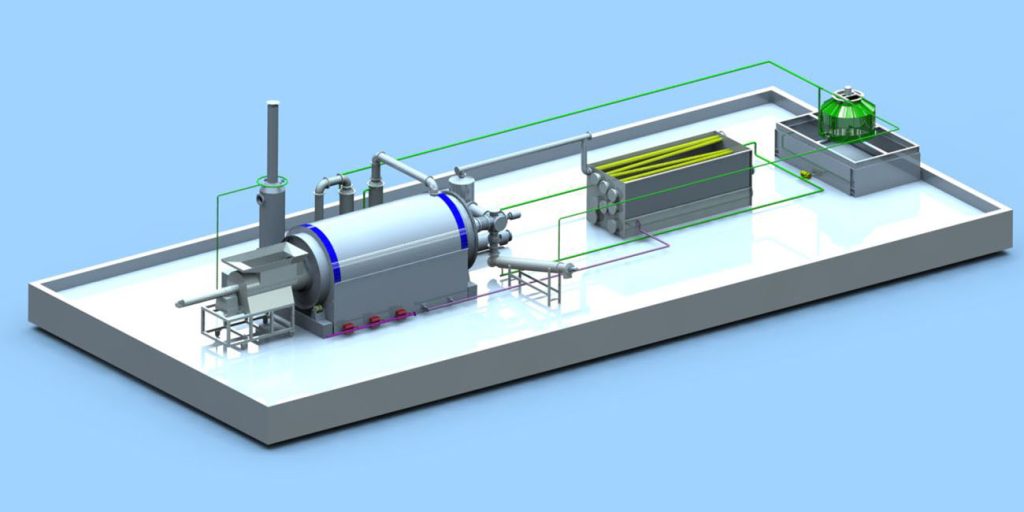

First, its investment is relatively small and the plastic pyrolysis plant cost is low. The plastic pyrolysis plant mainly includes pyrolysis reactor, condensation and cooling system, heating temperature control device and feeding and discharging device. For some enterprises with relatively limited funds or small plastic recycling plants, it has certain appeal.

Secondly, the pyrolysis process principle is easy to understand and master, and the pyrolysis machine operation is relatively simple. Mingjie batch pyrolysis equipment is equipped with a dewaxing device, which can effectively avoid the pipe blocking problem during the plastic pyrolysis treatment process.

Finally, in order to improve the purity of pyrolysis oil, Mingjie distillation equipment can further distill and refine black pyrolysis oil into bright diesel or gasoline base oil.

Mingjie Group is a professional plastic pyrolysis plant manufacturer in China. Pyrolysis plant can process a variety of organic wastes, including plastics, tires, biomass, oil sludge, municipal solid waste (MSW), Medical Waste and has a wide range of applications.

Mingjie Pyrolysis Plant Manufacturer has a research and development team composed of senior engineers and environmental experts, constantly promoting technological innovation. Our factory has a CNC equipment workshop with an area of 12,000 square meters, and the master has more than 20 years of experience in equipment manufacturing.

Our Plastic Pyrolysis Plants for sale are CE and ISO certified. We have provided customized environmental solutions to more than 200 customers around the world. And have successfully implemented a number of large-scale tire, plastic recycling, and biomass carbonization projects in more than 30 countries, winning wide recognition.

We provide plastic waste pyrolysis recycling machine for sale in two operation mode: batch and continuous.

The batch pyrolysis plant is divided into MJ-2 skid-mounted small pyrolysis plant and MJ-6 MJ-10 MJ-12 MJ-15 batch pyrolysis equipment of various models.

The continuous pyrolysis plant is divided into MJL-15 semi-continuous pyrolysis equipment and MLL-20T MLL-20P MLL-30 and more models of fully continuous pyrolysis equipment.

| Item | Content | |||

| Model | No. | Capacity | Reactor Size | Operation |

| MJ-2 | 1-2T per batch | 1400*4000mm | Batch | |

| MJ-6 | 6T/D | 2200*6000mm | Batch | |

| MJ-10 | 8-10T/D | 2600*6600mm | Batch | |

| MJ-12 | 12T/D | 2800*7100mm | Batch | |

| MJ-15 | 13-15T/D | 2800*8000mm | Batch | |

| MJL-15 | 15-16T/D | 2800*7100mm | Semi-continuous | |

| MLL-20P | 30T/D | 1600*26000mm | Fully continuous for plastics | |

| MLL-30T | 40T/D | 1600*26000mm | Fully continuous for tires | |

| Accepted materials | Waste tires/plastics, rubber/oil sludge/MSW/Medical Waste | |||

| End products | Pyrolysis oil, carbon black, steel wires , combustible gas | |||

| Applicable fuel | Coal/natural gas/LPG/ Diesel/wood/pyrolysis oil | |||

| Thickness of Reactor | 16mm/18mm | |||

| Cooling | Water Cooling | |||

| Land Required | 300-400m2 | |||

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..