· Product: MJ-2 pyrolysis plant

· Country: Peru

On May 6, 2025, Mingjie Group completed the shipment of MJ-2 Small Tyre Recycling Plant for sale to Peru. The MJ-2 mobile pyrolysis unit is skid-mounted and has a daily processing capacity of 1-2 tons. It is suitable for batch pyrolysis of waste tires, plastics and oil sludge.

The skid-mounted waste tire pyrolysis machine can be transported by 40HQ container. Its installation is mainly completed in Mingjie pyrolysis plant manufacturing factory, thus reducing the workload of customer on-site installation.

The skid-mounted waste tire pyrolysis equipment provides enterprises with a low-risk, high return on investment solution. The skid-mounted tire pyrolysis plant cost is lower than that of continuous pyrolysis plants. It can be flexibly and quickly deployed in waste pyrolysis projects and meets global environmental standards.

In order to quickly and fully pyrolyze waste tires, the customer also purchased a tire cutting machine. We provide a small tire cutting machine that matches the MJ-2 mobile Small Tyre Recycling Plant for Sale to Peru. Tire cutting and waste tire pyrolysis are two key links in the waste tire treatment process, and they constitute an important chain of waste tire recycling.

The pyrolysis process has certain requirements on the size of waste tires. If the size of the tire after cutting is too large, it will lead to low heat transfer efficiency and incomplete pyrolysis reaction. If the size is too small, it will increase the cutting cost and energy consumption, and it may also cause the material to flow poorly in the Small Tyre Recycling Plant. Therefore, it is necessary to determine the appropriate cutting size according to the type of waste tire pyrolysis machine and process requirements.

The MJ-2 skid-mounted Small Tyre Recycling Plant for Sale to Peru is mainly composed of a feeding unit, a pyrolysis reactor, a condensation recovery system, an exhaust gas treatment device and a control system. Each system is quickly connected through pipes and cables to support rapid assembly on site.

In the pretreatment stage, tire cutting equipment is required to disassemble the waste tires into block materials to ensure uniform feed particle size. The cut materials are fed into the waste tire pyrolysis machine. A sealed gate valve is set at the feed port to maintain an oxygen-free environment in the reactor.

The waste tire pyrolysis is a process of heating waste tires to a certain temperature under oxygen-free or oxygen-deficient conditions to cause thermal decomposition reactions. Finally, waste tires are converted into synthesis gas, liquid fuel oil and solid carbon black.

The heating method is mainly indirect heating, and the heat source can come from natural gas and biomass fuel. It can also use the syngas produced by tire pyrolysis (calorific value of about 18-22MJ/Nm³) to achieve an energy self-sufficiency rate of 30%-50%.

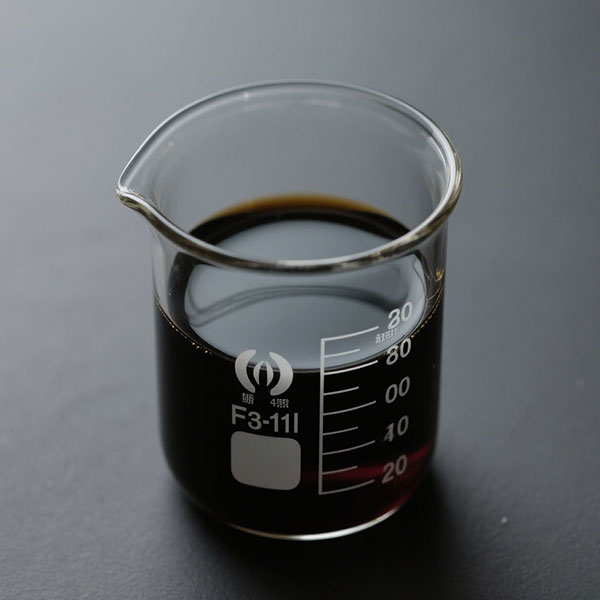

Pyrolysis oil and gas condensation: The oil and gas mixture discharged from the pyrolysis reactor enters the condenser. The liquid pyrolysis oil (calorific value of about 35MJ/kg) flows into the oil storage tank. The uncondensed non-condensable gas enters the tail gas treatment unit.

Solid residue treatment: After the pyrolysis of waste tires is completed, the reactor is unloaded. The mixture of carbon black and steel wire can be separated by vibration screening + magnetic separation.

Tail gas recycling: After desulfurization and dust removal, part of the non-condensable gas is used as reactor heating fuel, and the remaining part meets the emission standards.

· Product: semi-continuous waste tires pyrolysis plant

· Country: Australia

· Nissan: daily capacity 30T

· Country: Lebanon