The amount of plastic waste generated globally has far exceeded the capacity of mechanical recycling. Plastic pyrolysis technology offers advantages such as broad adaptability to…

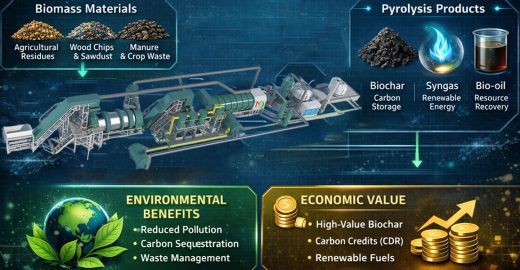

Continuous biomass pyrolysis plant breaks away from the batch pyrolysis model, enabling continuous feeding of biomass raw materials and continuous discharge of biochar. The biochar…

Aluminum plastic composite materials are widely used in packaging, construction, electronics, medical, and many other fields due to their excellent properties such as lightweight, moisture…

The core equipment of plastic pyrolysis to fuel oil plant mainly includes pyrolysis plant and pyrolysis oil distillation plant. The pyrolysis equipment converts waste plastics…

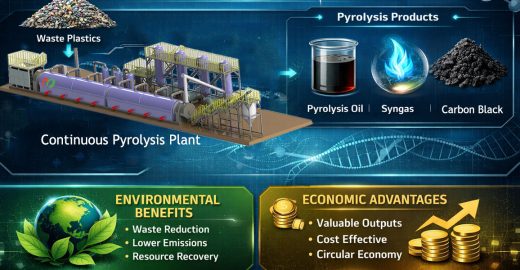

The plastic waste pyrolysis plant is an economical and efficient waste plastic treatment equipment that can convert waste plastics into fuel oil, combustible gas, and…

Continuous biomass pyrolysis is a key technology with significant environmental value, energy value, and carbon reduction potential. Through large-scale, continuous operation, biomass pyrolysis equipment provides…

Continuous plastic pyrolysis plant, as a chemical recycling solution, is gradually becoming an important solution for plastic recycling and low-carbon transition. Continuous pyrolysis plants continuously…

The core of waste plastic to fuel conversion lies in reversing the polymerization process. Pyrolysis technology can transform these plastic wastes back into their original…