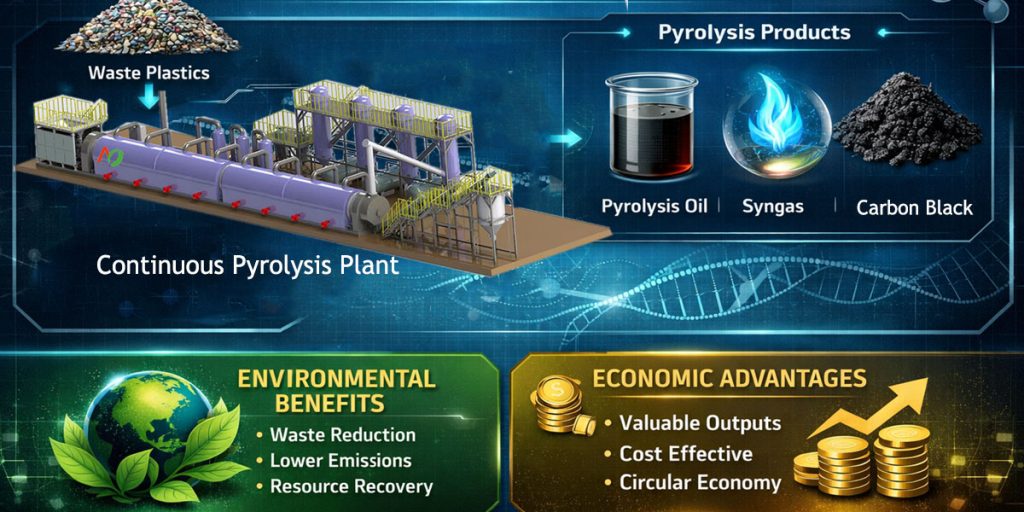

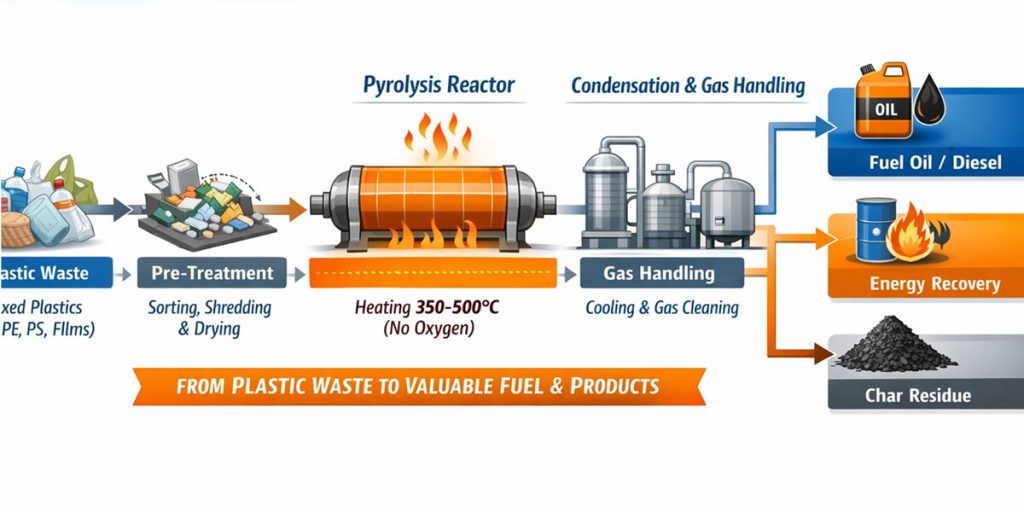

Continuous plastic pyrolysis plant, as a chemical recycling solution, is gradually becoming an important solution for plastic recycling and low-carbon transition. Continuous pyrolysis plants continuously convert waste plastics into pyrolysis oil, syngas, and solid residue, achieving resource utilization.

Compared to batch processes, continuous plastic pyrolysis demonstrates more significant overall benefits in both environmental and economic aspects.

Continuous plastic pyrolysis plant can process mixed waste plastics on a large scale and in a stable manner. It reduces white pollution, marine plastic pollution, and the risk of microplastic dispersion. Plastic pyrolysis plant can significantly alleviate the pressure on solid waste disposal in cities and industrial parks.

Compared to physical recycling, which has high requirements for raw material cleanliness, continuous pyrolysis can process difficult-to-recycle plastics. Continuous plastic pyrolysis provides an effective path for the end-of-life plastics management.

Under reasonable design and operating conditions, continuous pyrolysis has significant potential for carbon emission reduction. It avoids the direct emission of CO₂, NOₓ, and dioxins during plastic incineration. The pyrolysis oil produced can replace a portion of fossil fuels, indirectly reducing emissions from crude oil extraction and refining. The combustible gas generated by the continuous pyrolysis system can be used for self-heating, achieving a closed-loop energy cycle.

In life cycle assessment (LCA), continuous plastic pyrolysis generally outperforms incineration and landfill. It is considered an important low-carbon technology for plastic chemical recycling.

Continuous pyrolysis system is typically equipped with comprehensive environmental protection devices. Plastic pyrolysis operates continuously in a closed system, reducing pollution. It integrates pyrolysis, oil and gas recovery, and automatic carbon black discharge.

Multi-stage condensation, tail gas combustion, and scrubbing systems reduce VOCs and acid gas emissions. Provided that emission standards and operating regulations are met, the environmental risks are relatively controllable.

The rise of continuous pyrolysis technology for waste plastics has given rise to a series of new industries, injecting new vitality into economic development. The pyrolysis equipment manufacturing industry has emerged. With the continuous development and application of pyrolysis technology, the demand for efficient, environmentally friendly, and intelligent pyrolysis equipment is growing.

The construction of waste plastic recycling networks has also become a new industrial sector. To ensure a stable supply of raw materials for pyrolysis plants, a broad and efficient waste plastic recycling network needs to be established. This complete system includes waste plastic collection, sorting, transportation, and storage.

Related service industries surrounding continuous waste plastic pyrolysis have also developed, such as technical consulting, engineering design, equipment maintenance, and environmental monitoring. This provides comprehensive support for the planning, construction, and operation of pyrolysis projects.

Plastic pyrolysis oil partially replaces traditional fossil fuels. This reduces dependence on imported fossil resources such as petroleum. Pyrolysis oil can be used directly as fuel in industrial boilers, kilns, and other equipment, meeting some of the energy needs of industrial production. Further refining and processing of pyrolysis oil can also convert it into transportation fuels such as gasoline and diesel.

Pyrolysis gas and carbon black also have significant economic value. Pyrolysis gas, as a fuel gas, can be used for the energy supply of the pyrolysis plant itself, reducing energy costs in the production process. Carbon black is an important raw material for industries such as rubber and ink. Recycling and utilizing pyrolysis carbon black reduces the need for mining natural carbon black resources.

Compared to batch pyrolysis, continuous plastic pyrolysis plant offers significant economic advantages and a considerable ROI.

An Australian general waste and tire recycling authoritative body turned to Environment Minister Sussan Ley in November last year with a request to prohibit whole bale tire…

Aliapur – a French end-of-life tire management authority – recently announced a call for applications to participate in a tender to renew end-of-life tire collection and recycling contacts for 2021–2024..