Tire pyrolysis plant can convert waste tires into pyrolysis oil, syngas, steel wire, and carbon black. The main application areas of waste tire to oil…

Making biochar from animal manure is a highly promising waste resource utilization pathway. It connects animal husbandry, environmental protection, and agriculture, aligning with the concept…

The core contribution of waste biomass pyrolysis technology to energy and environmental protection lies in transforming waste into valuable resources. It not only produces renewable…

Pyrolysis technology, as an advanced end of life tire recycling solution, can yield tire pyrolysis oil (TPO), carbon black, steel wire, and syngas. Tire pyrolysis…

In municipal solid waste management, pyrolysis technology demonstrates exceptional volume reduction capabilities in the plastic waste disposal. It is gradually becoming a key force in…

Waste oil to diesel machine can process various waste oils, converting them into clean diesel fuel. The core principle of a waste oil to diesel…

Turning plastic into fuel, as an emerging method for plastic waste treatment and resource recycling, has received widespread attention globally in recent years. The conversion…

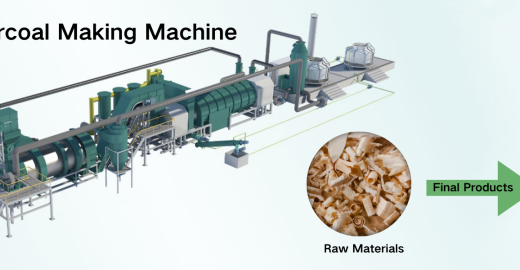

Sawdust pyrolysis machine adopts an advanced thermochemical conversion technology, providing a sustainable solution for sawdust recycling. It can convert this waste into high-value products, including…